Our Work

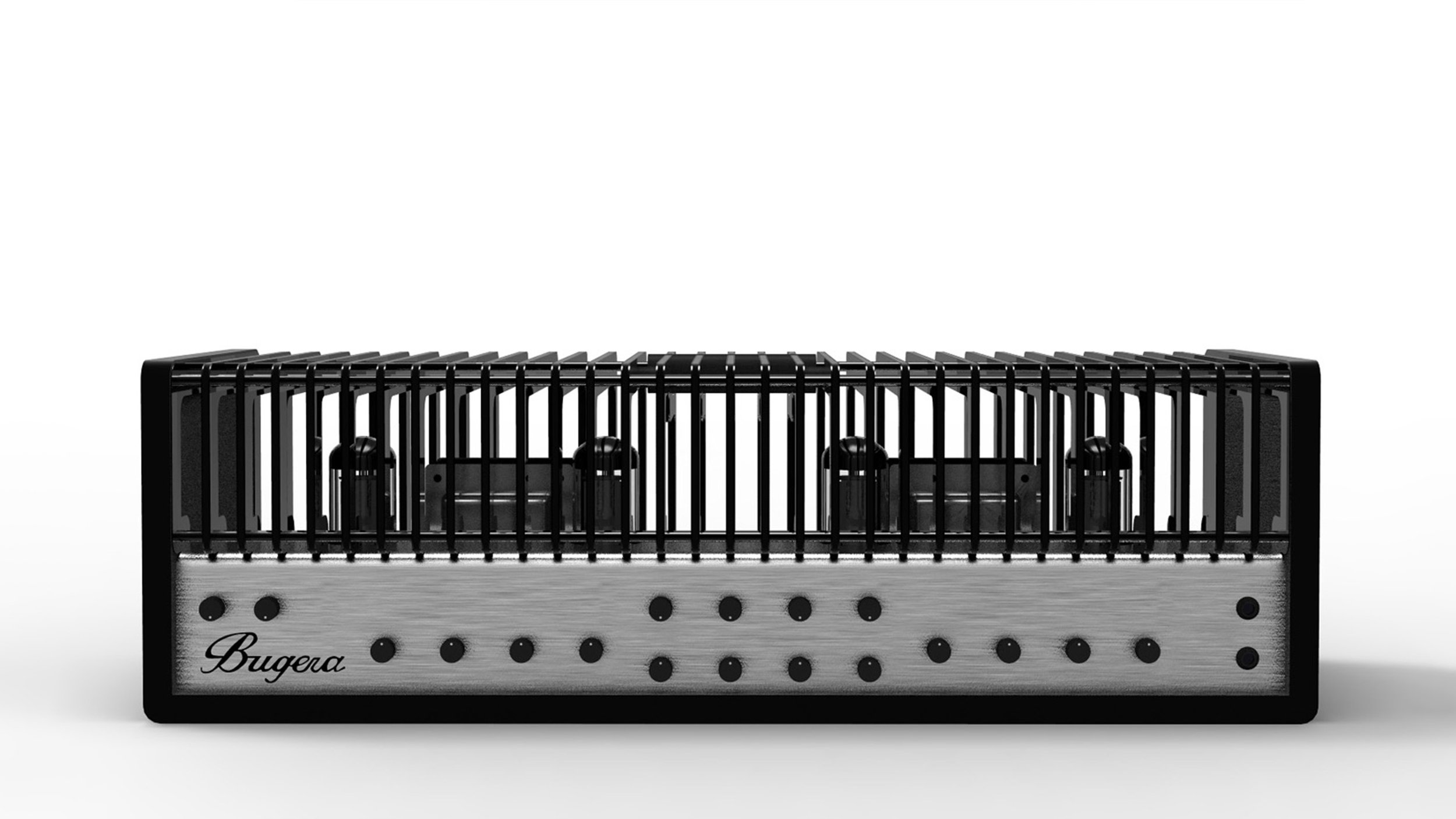

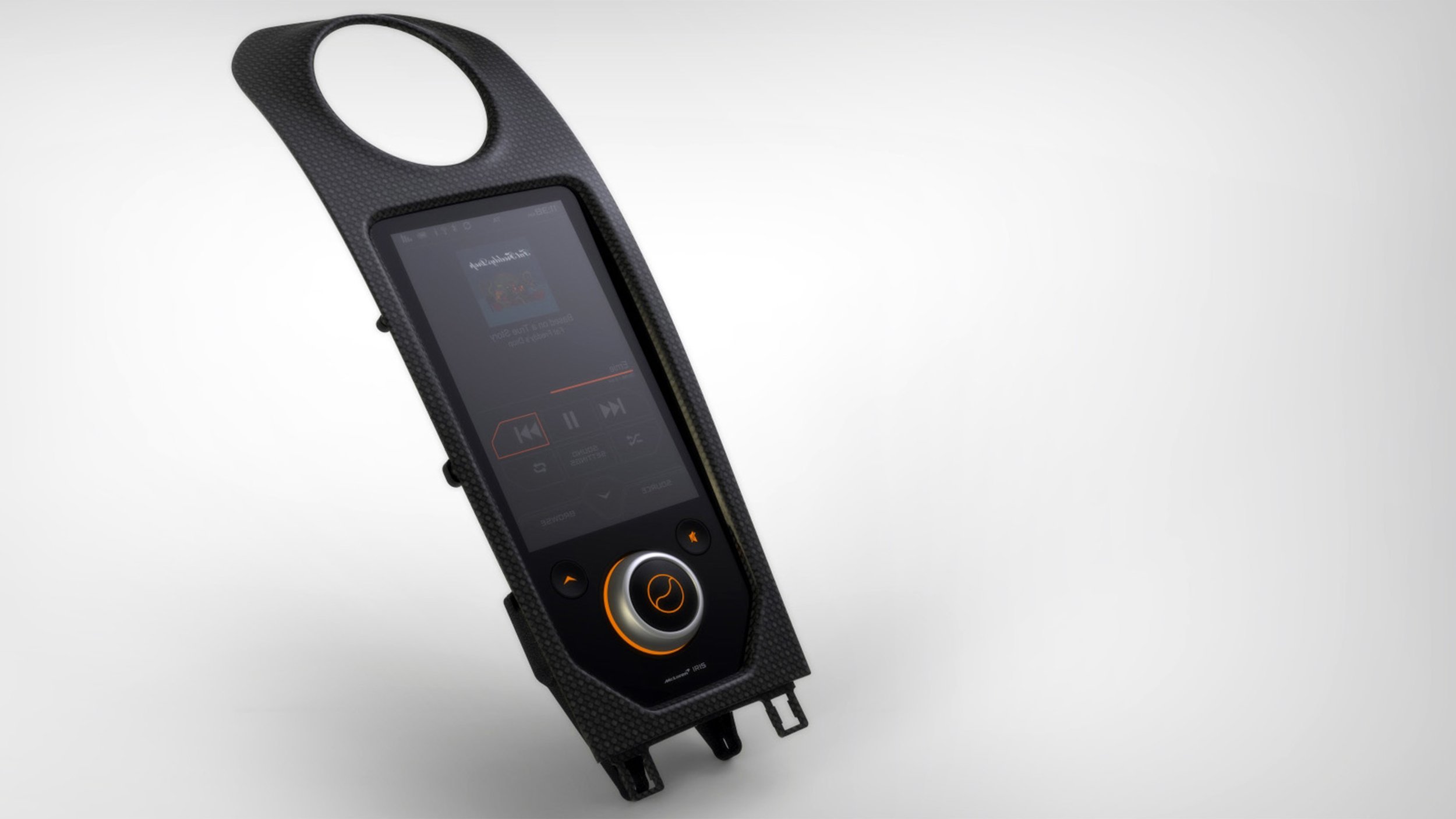

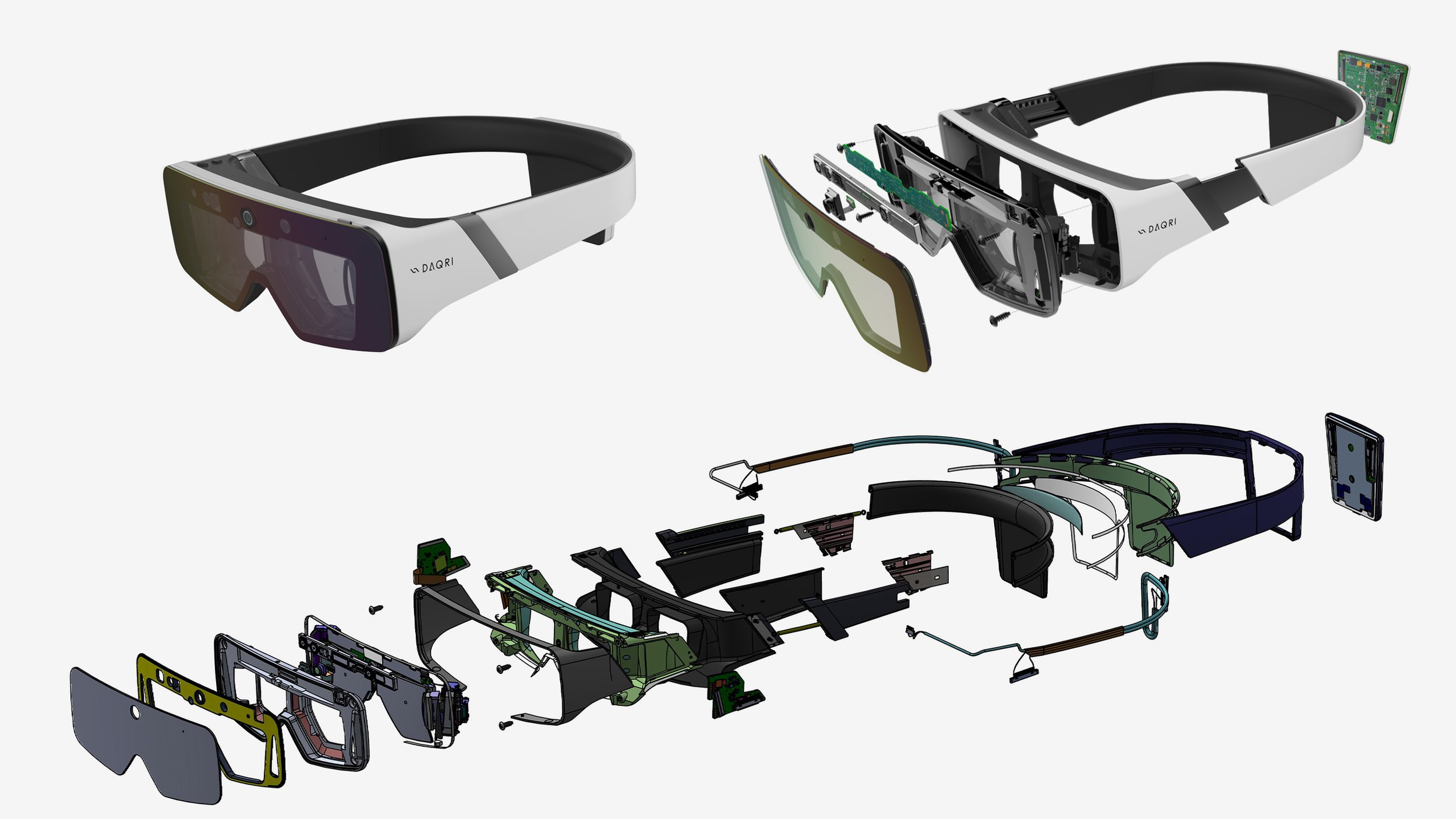

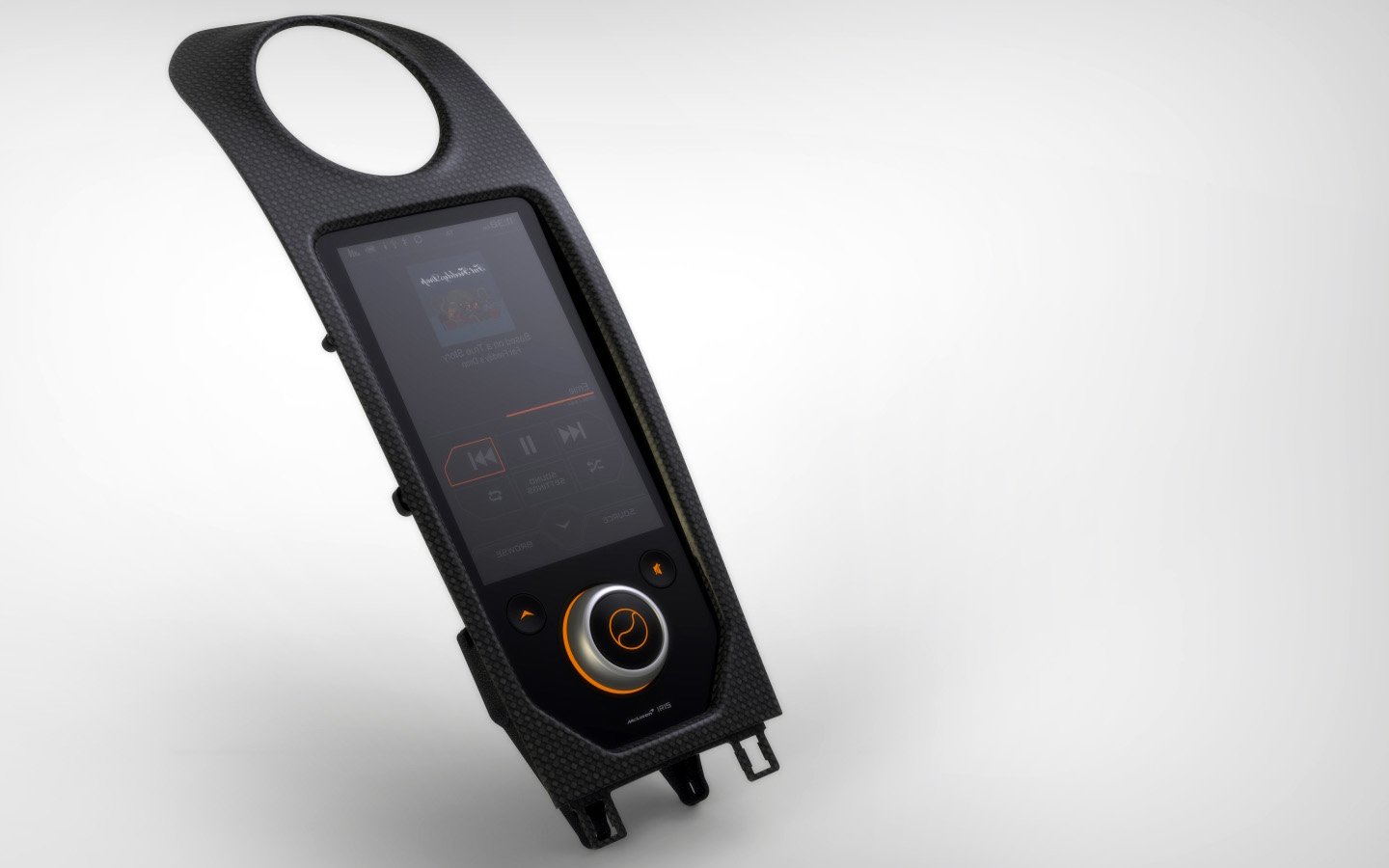

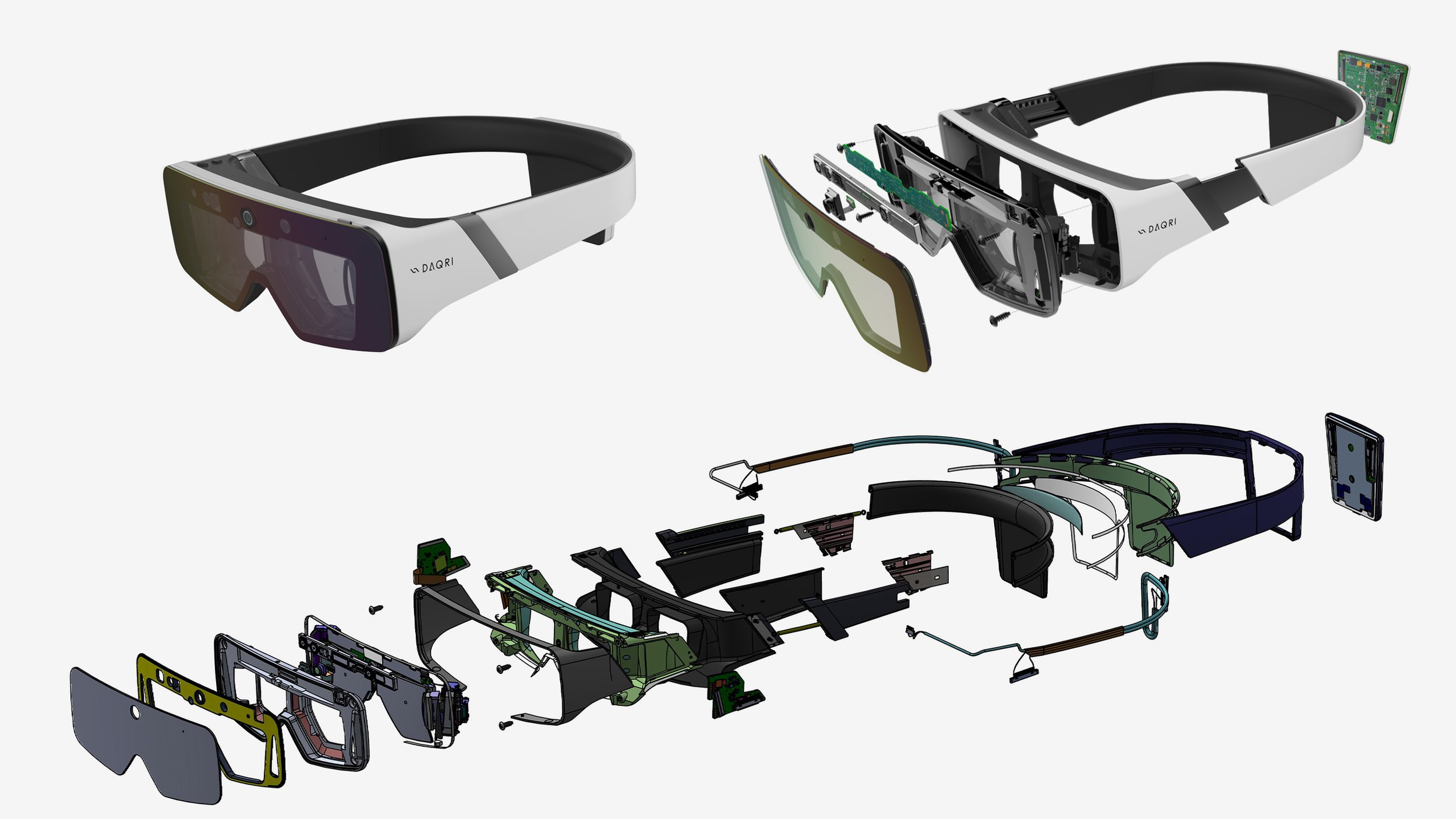

VX Inc. provides a full range of product development services with a focus on wearable technology. We enjoy the kind of projects that are too difficult for traditional design & development firms.

Our methodical process gets results.

Our engineers have accumulated broad expertise in development.

Our results are distinguished.

Examples of our work and influence can be found throughout the industry, going back a decade.

Services

Industrial Design

Mechanical Engineering

Electrical Engineering

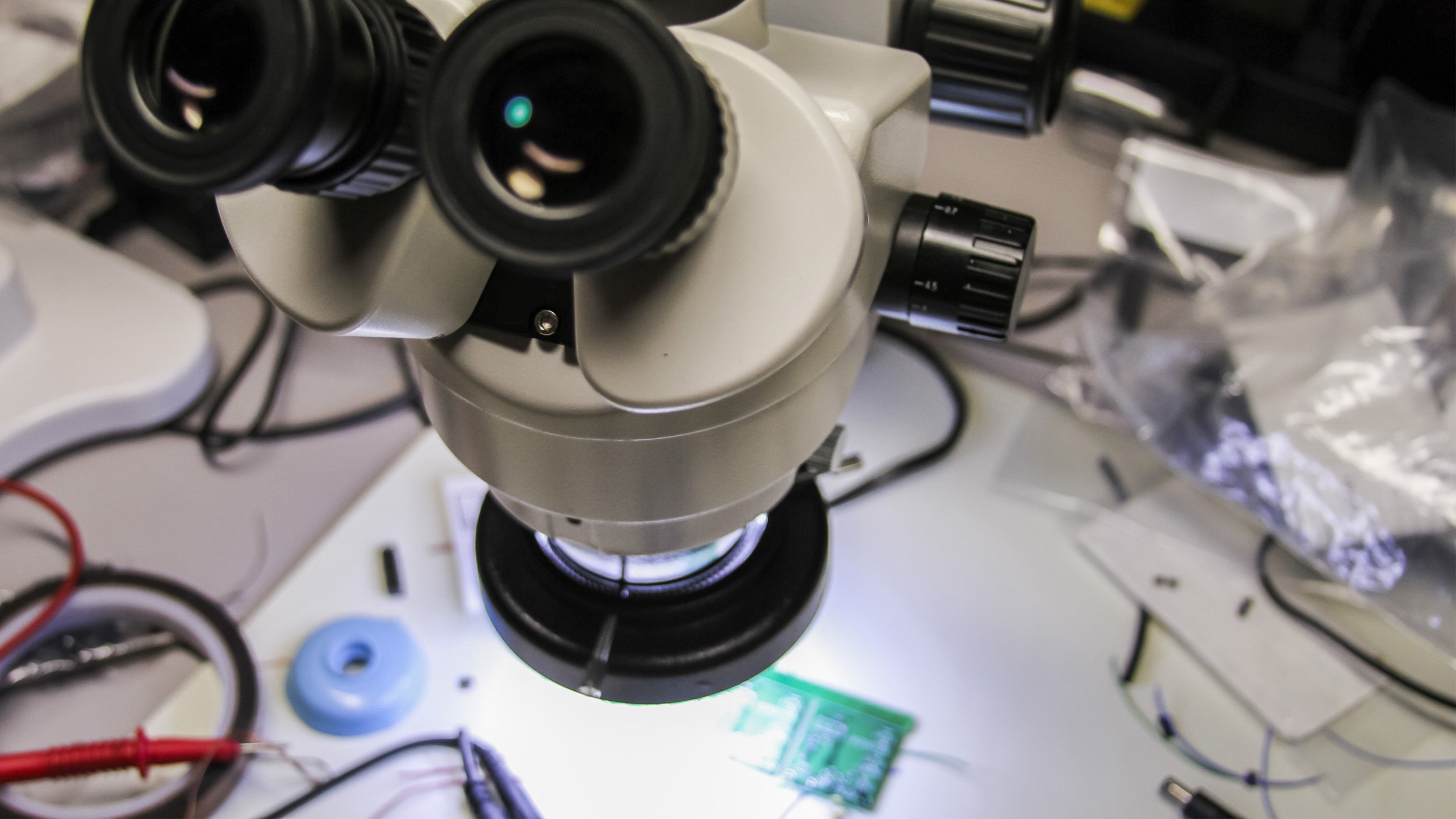

Optical Engineering

Manufacturing Consulting

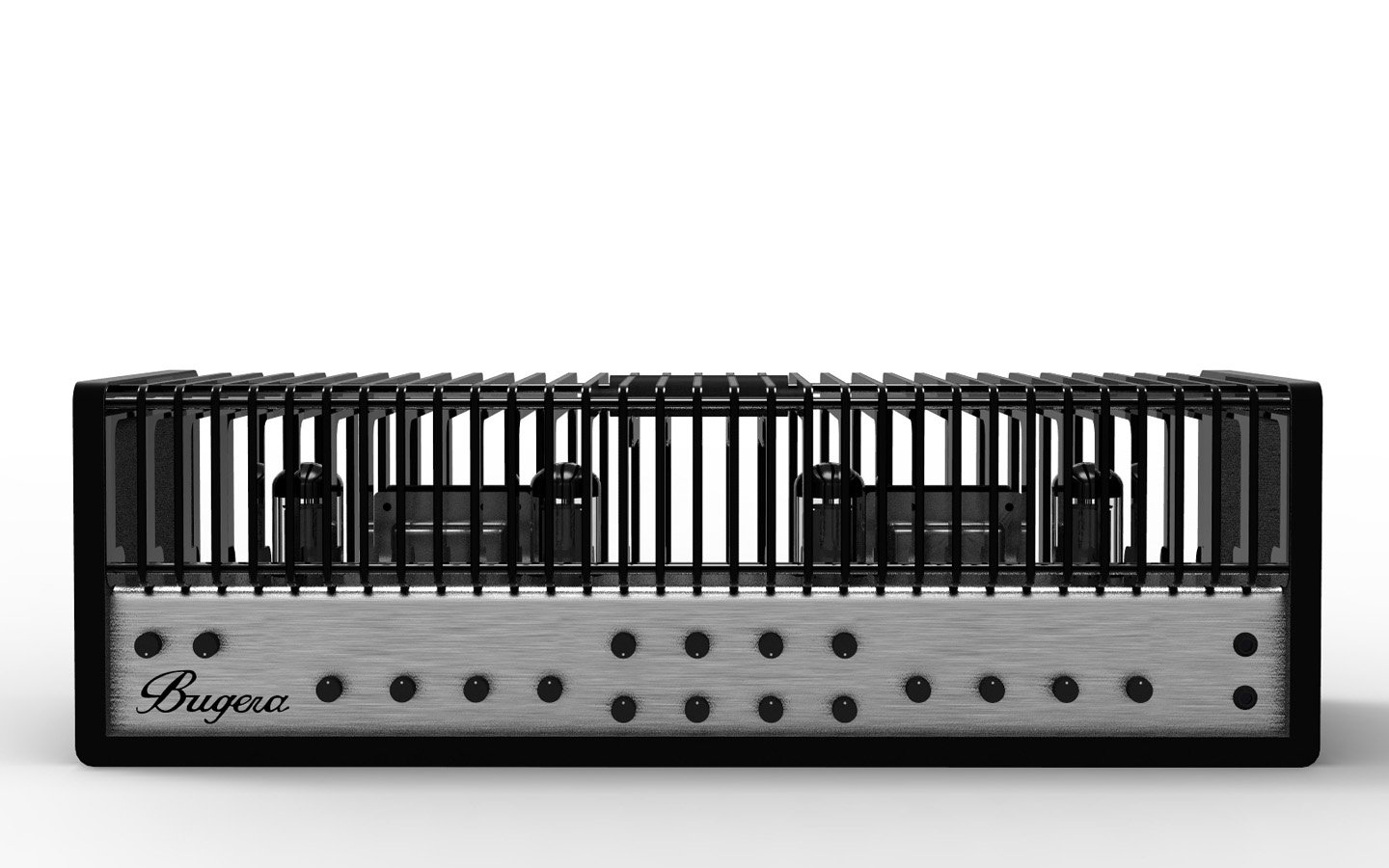

Industrial Design

A good industrial design is key to make any produced product come to life. Good design can define a product, maximize profit and boost sales.

We offer a full range of design, product planning, concept rendering, and human factors services.

Design Focused Manufacturing

User Experience

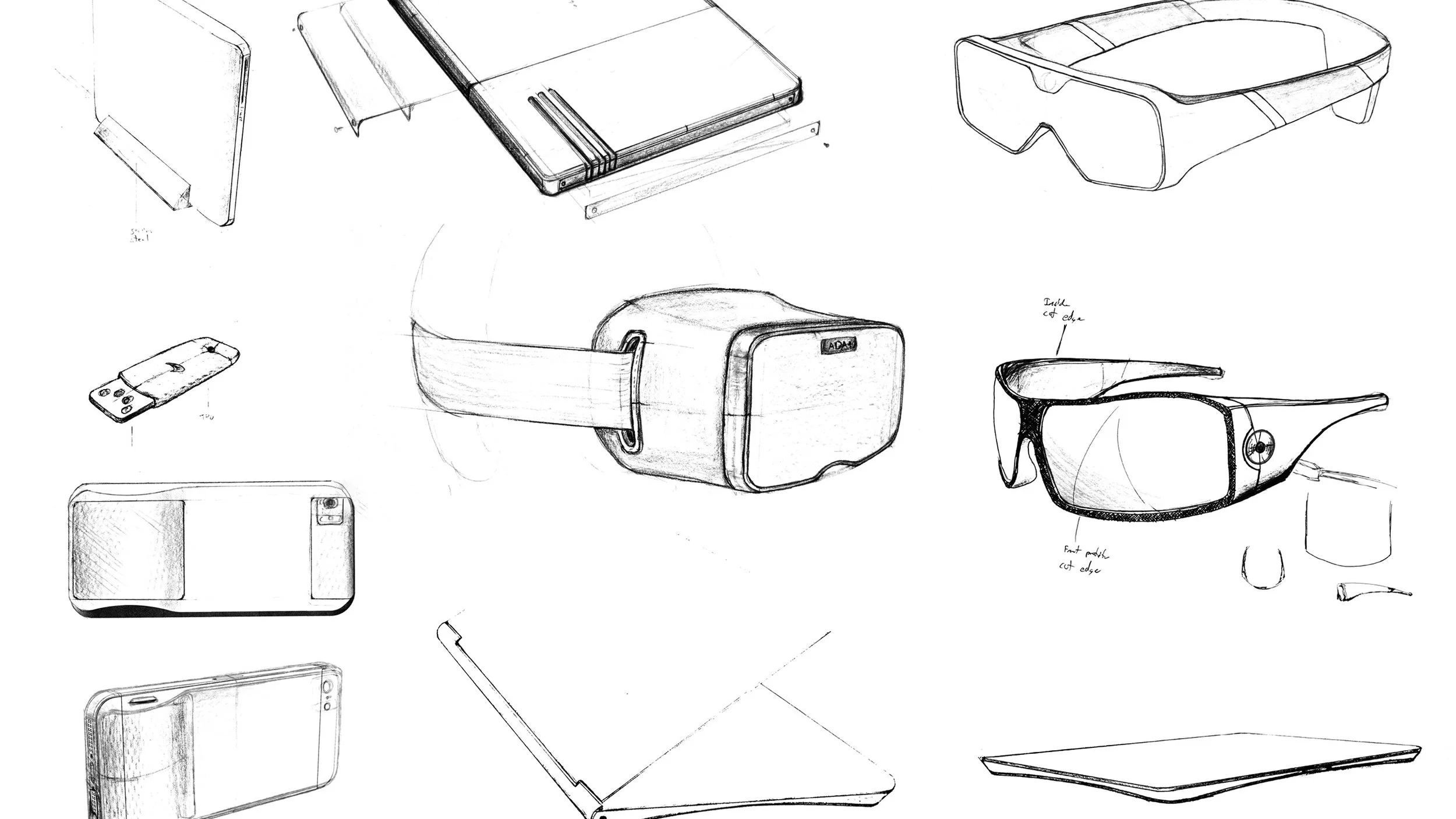

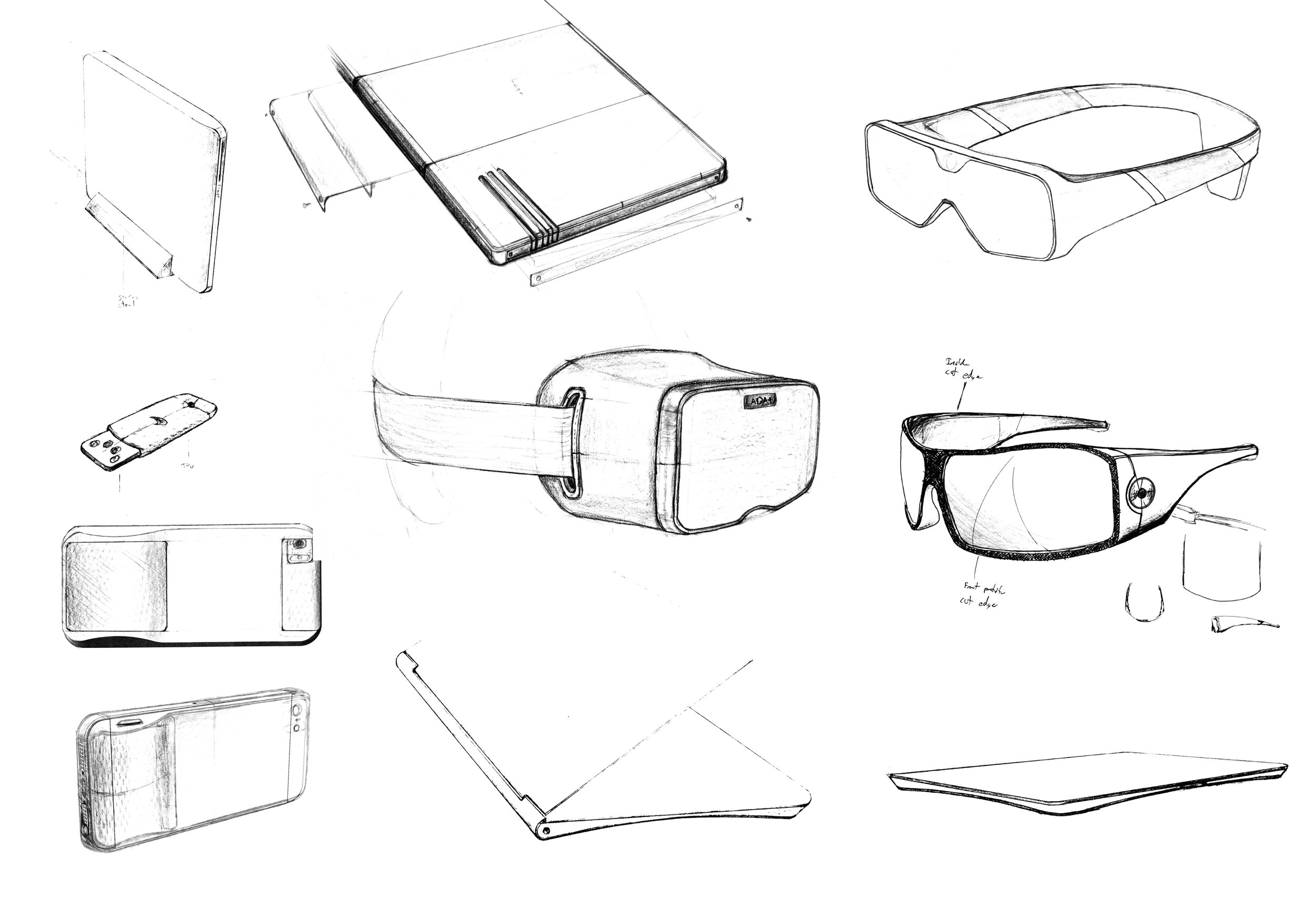

Concept Ideation

3D Rendering

Human Factors

Color, Material, Finish

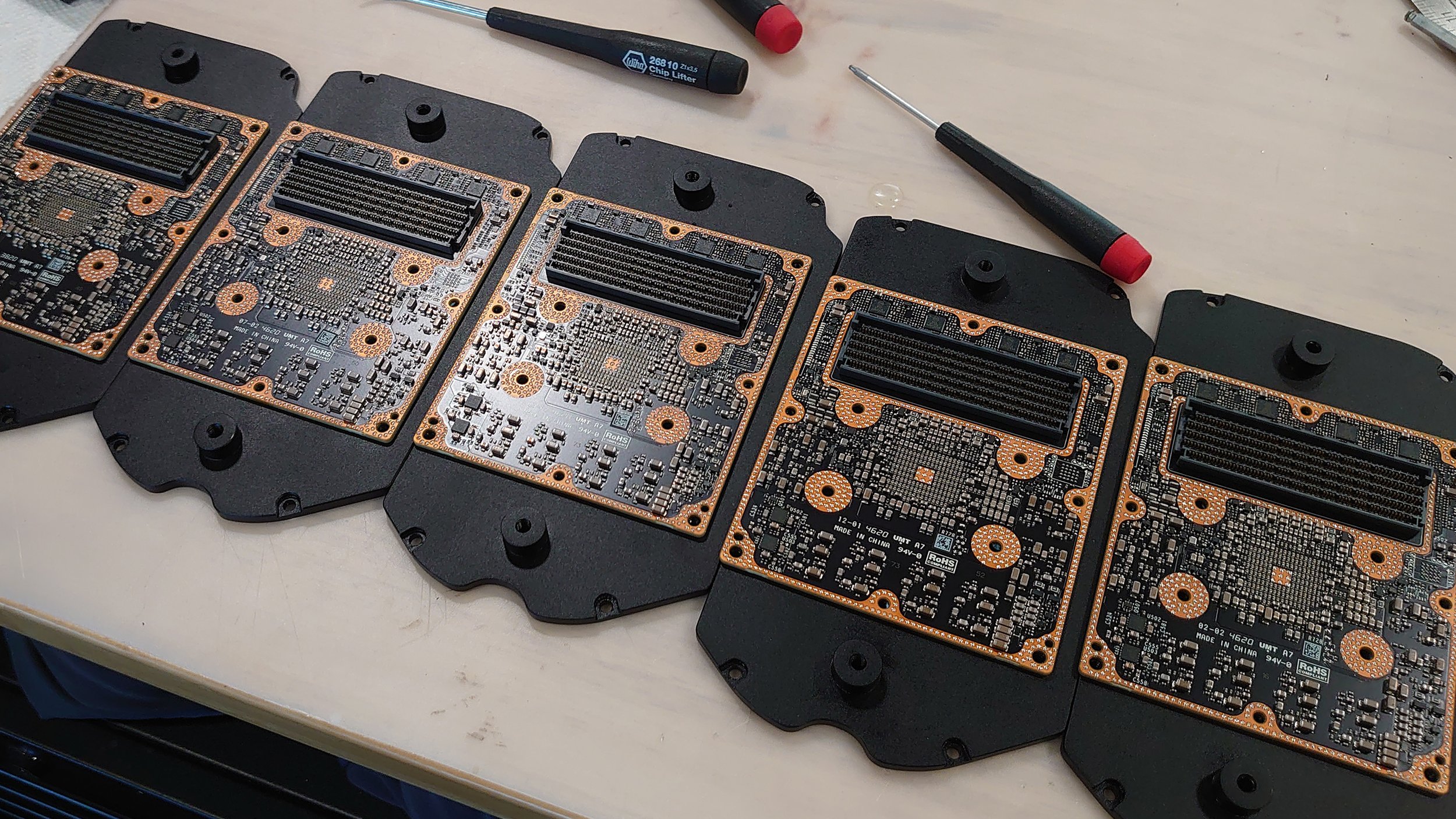

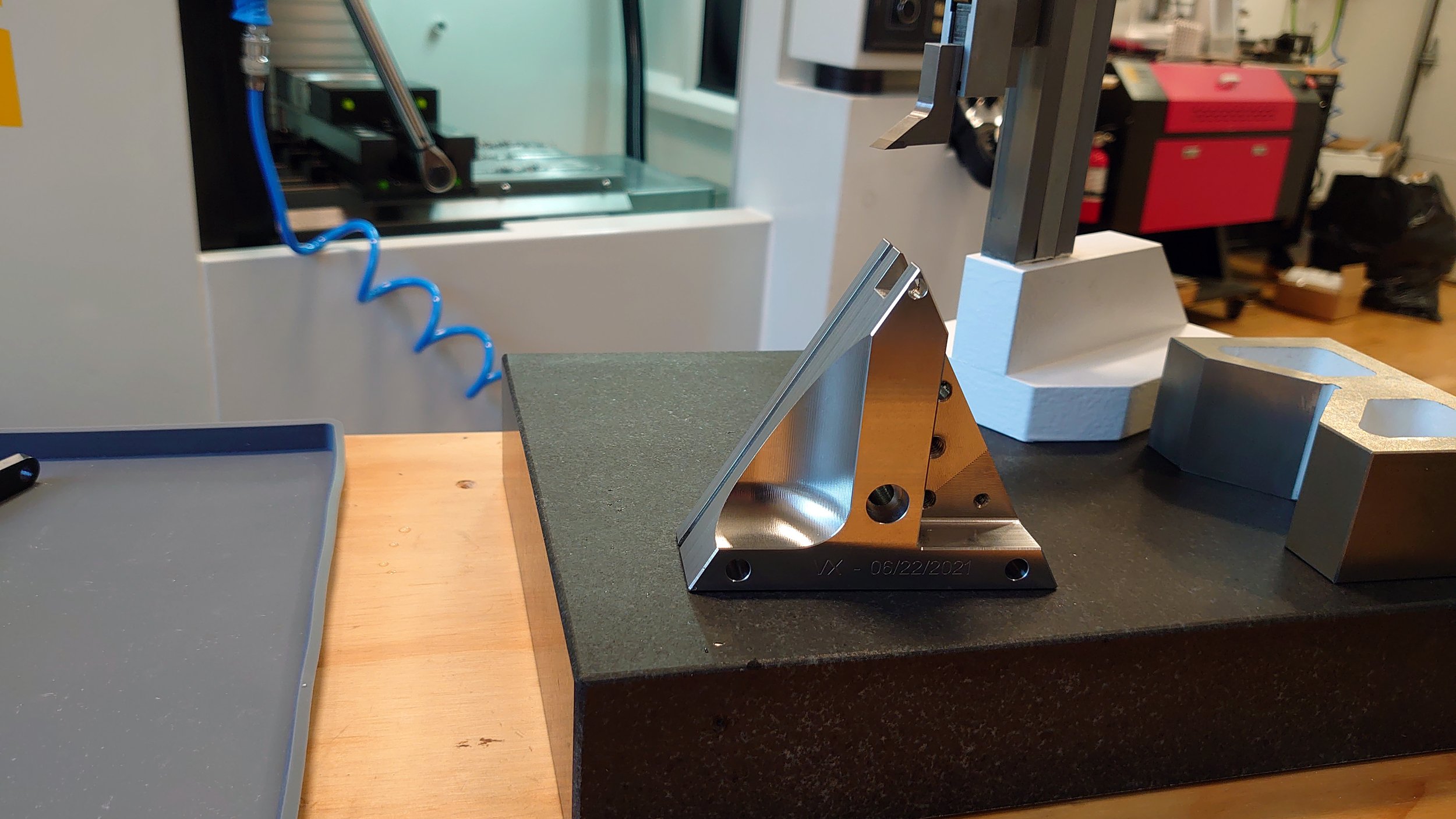

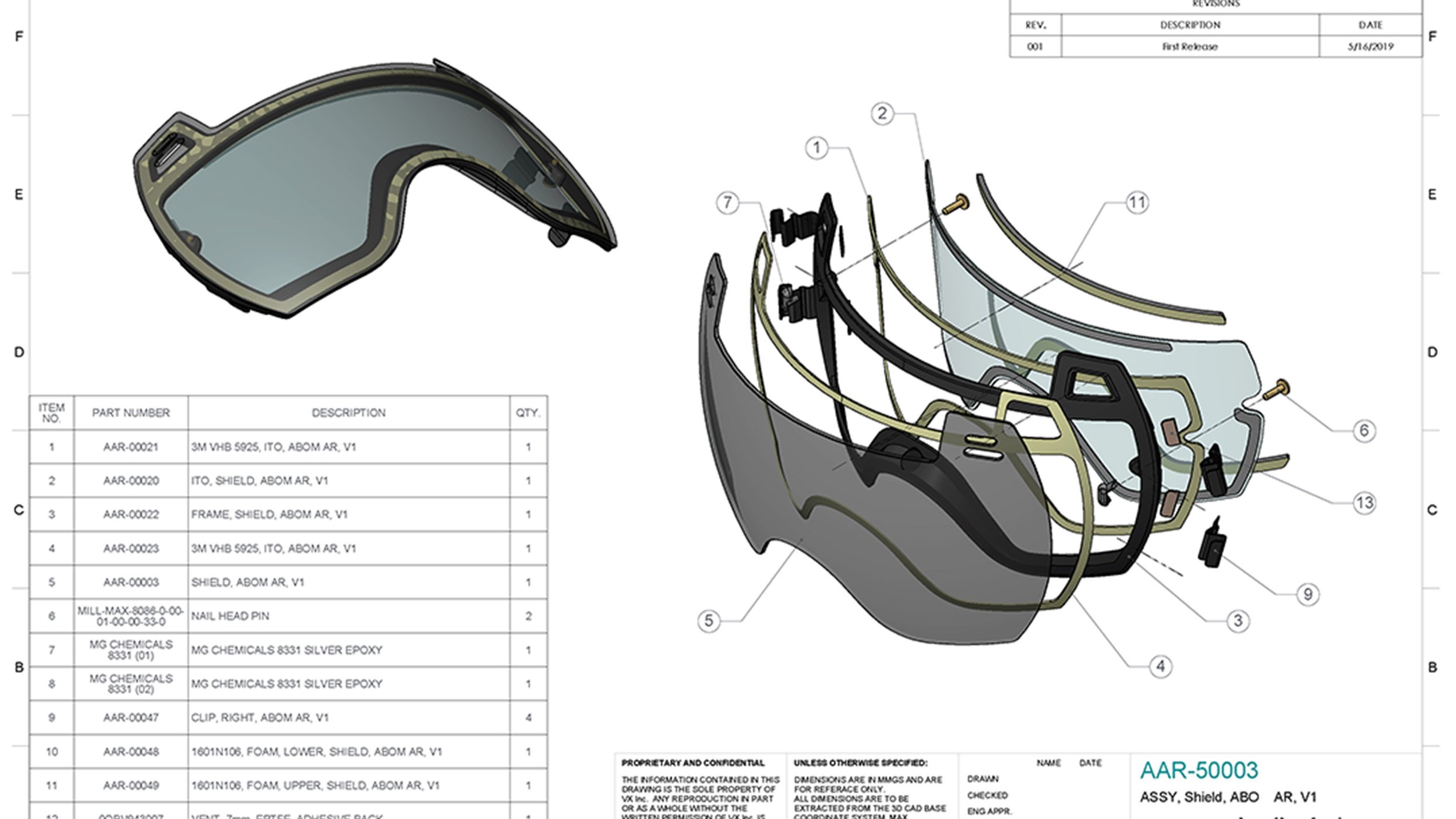

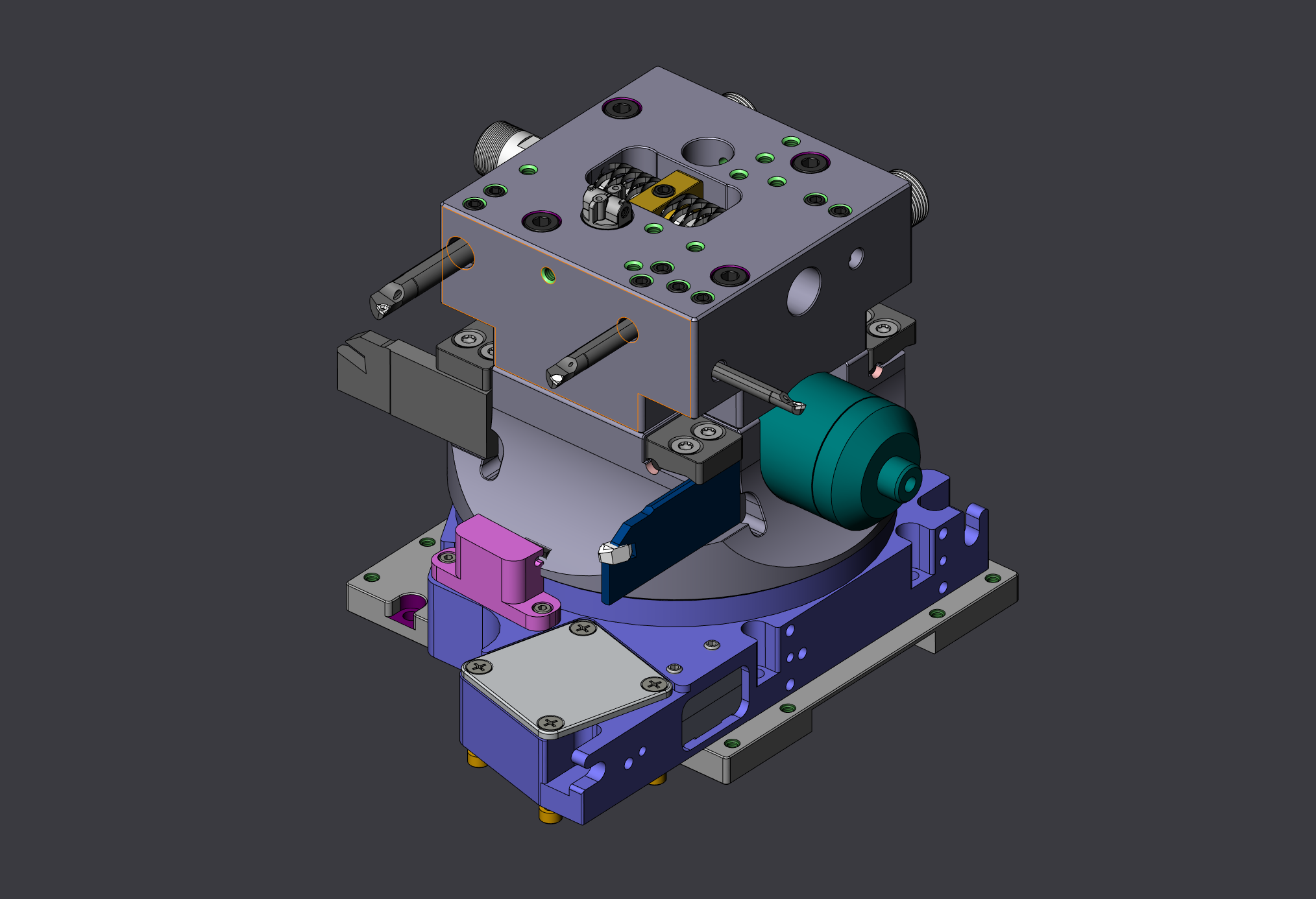

Mechanical Engineering

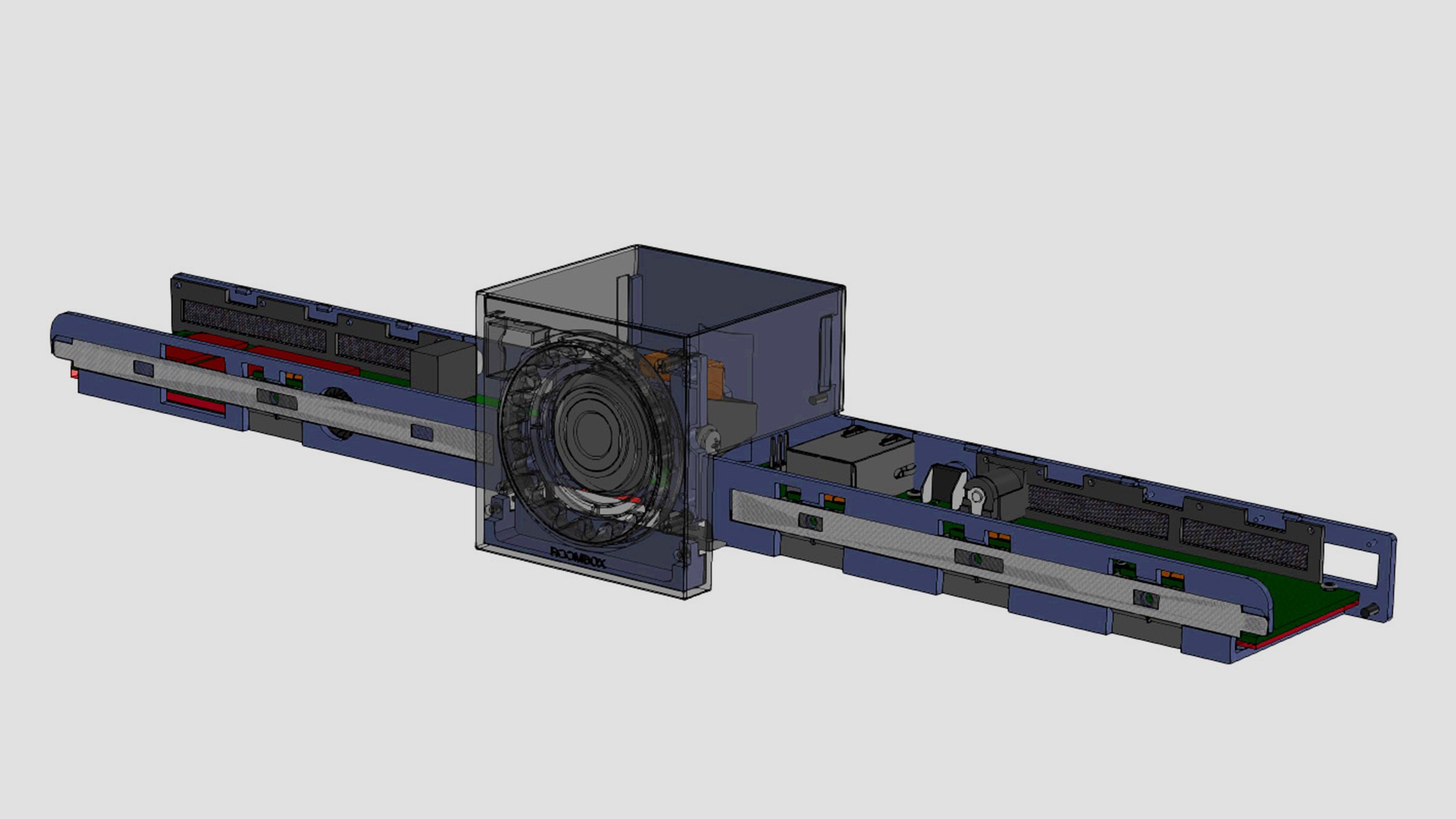

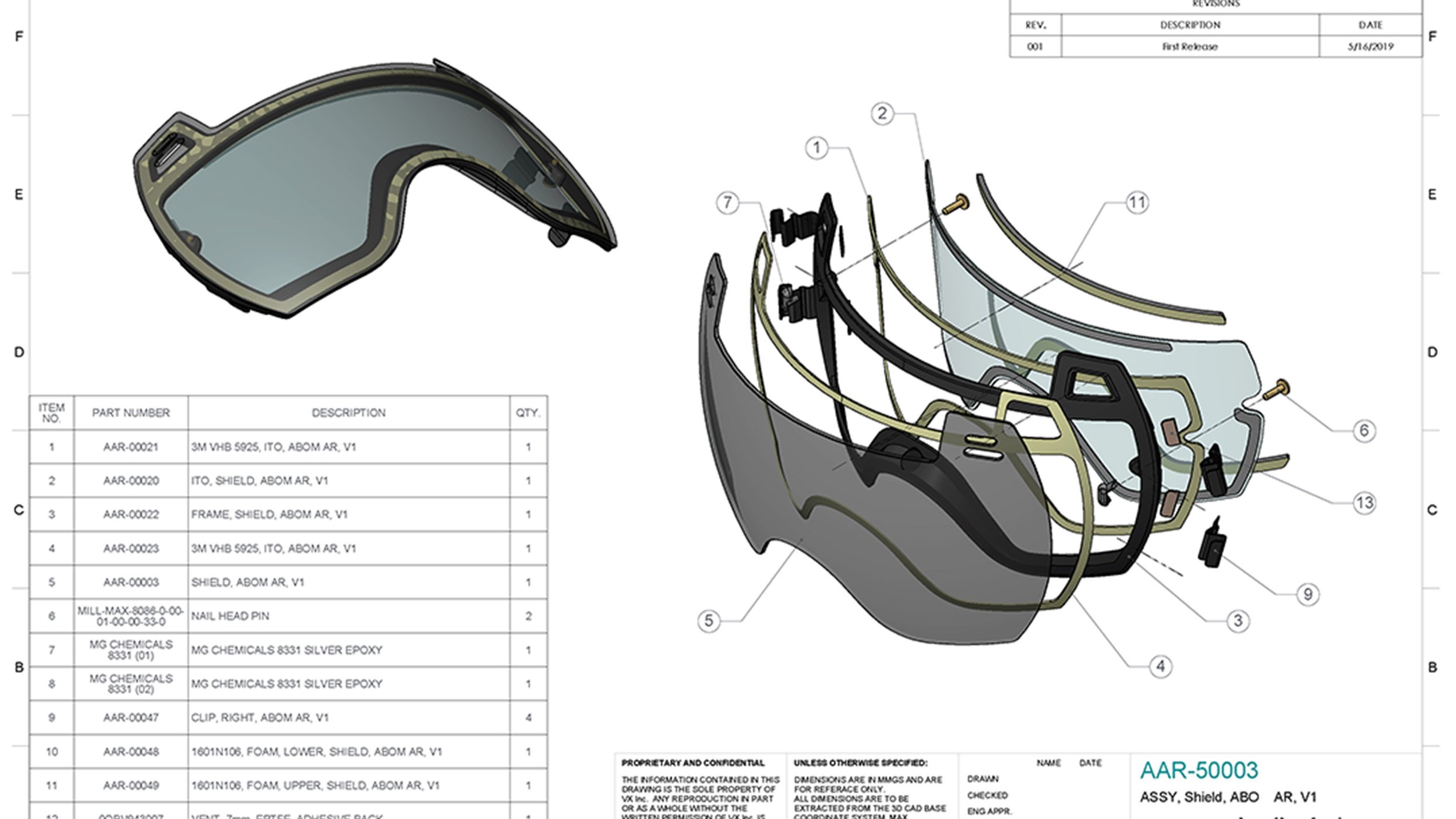

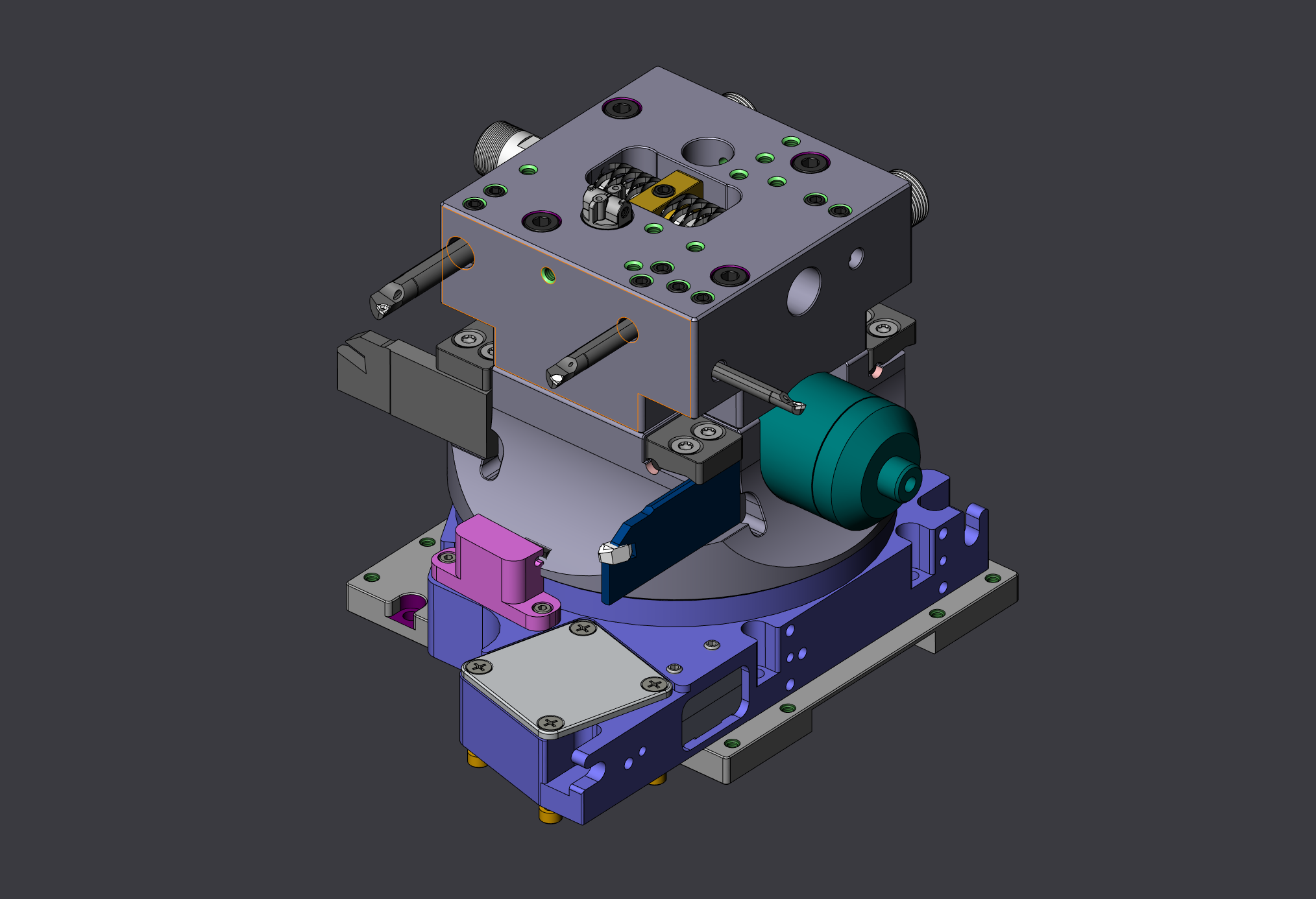

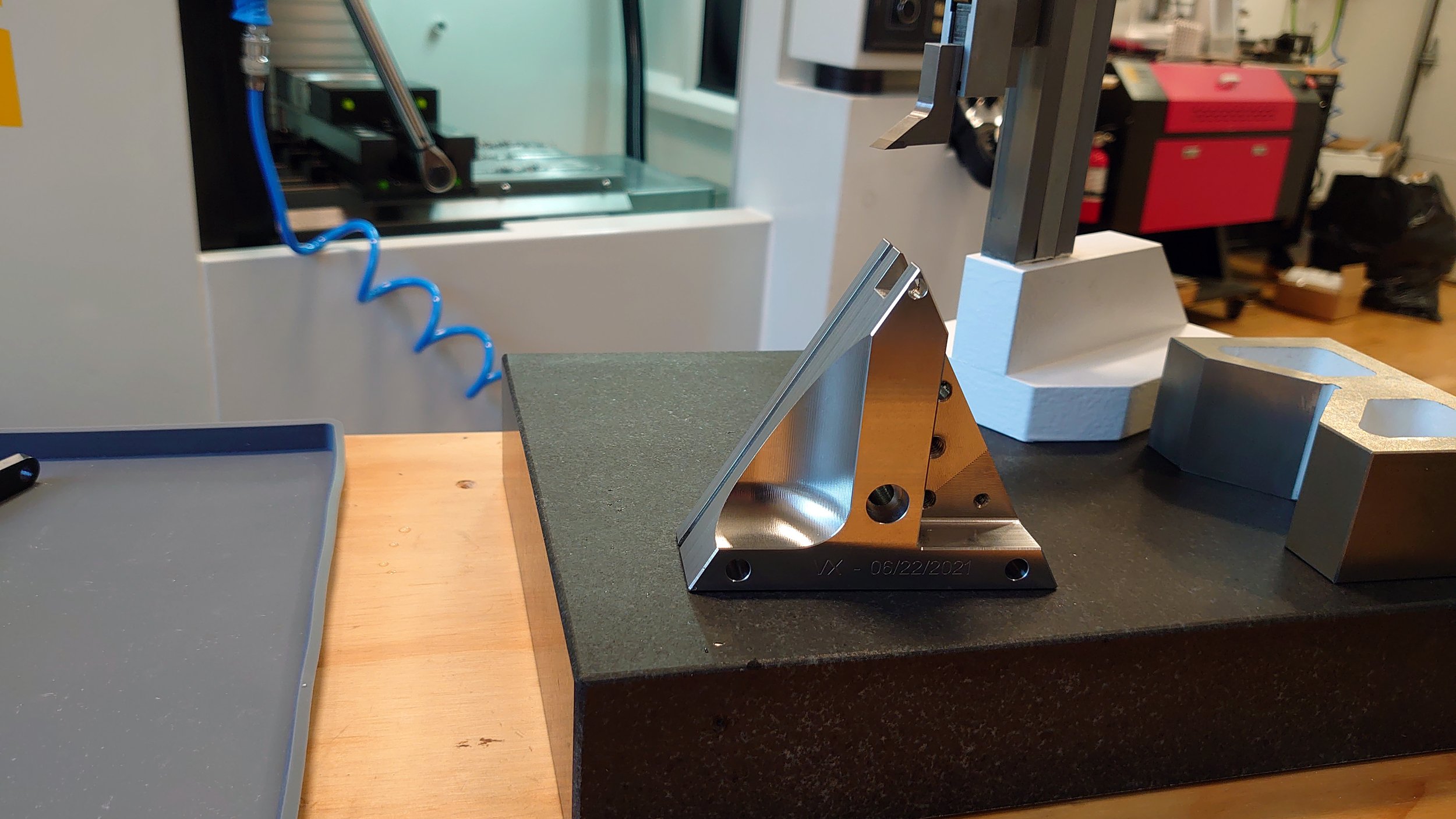

Our engineers are development experts with a passion for good design, electromechanics, optomechanics, and advanced manufacturing.

Our broad expertise allows us to design, analyze, fabricate, and test complicated mechanical systems. We specialize in compact, rugged, and harsh environment devices.

Design for Manufacturing and Assembly

3D Modeling and 2D Drawings

Manufacturing Packages

Tooling Design

IP6X, Z87, MIL-PRF, UL

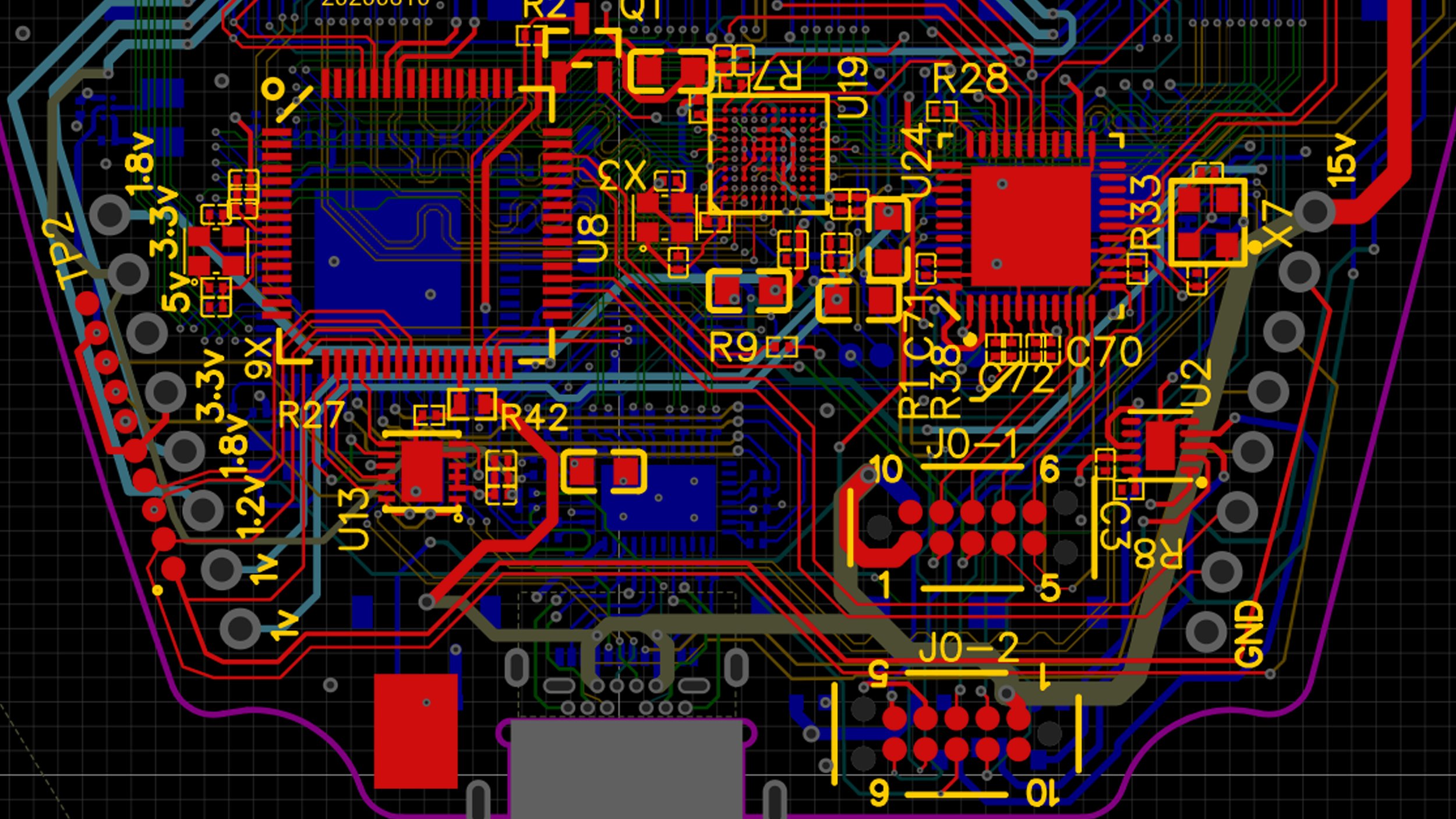

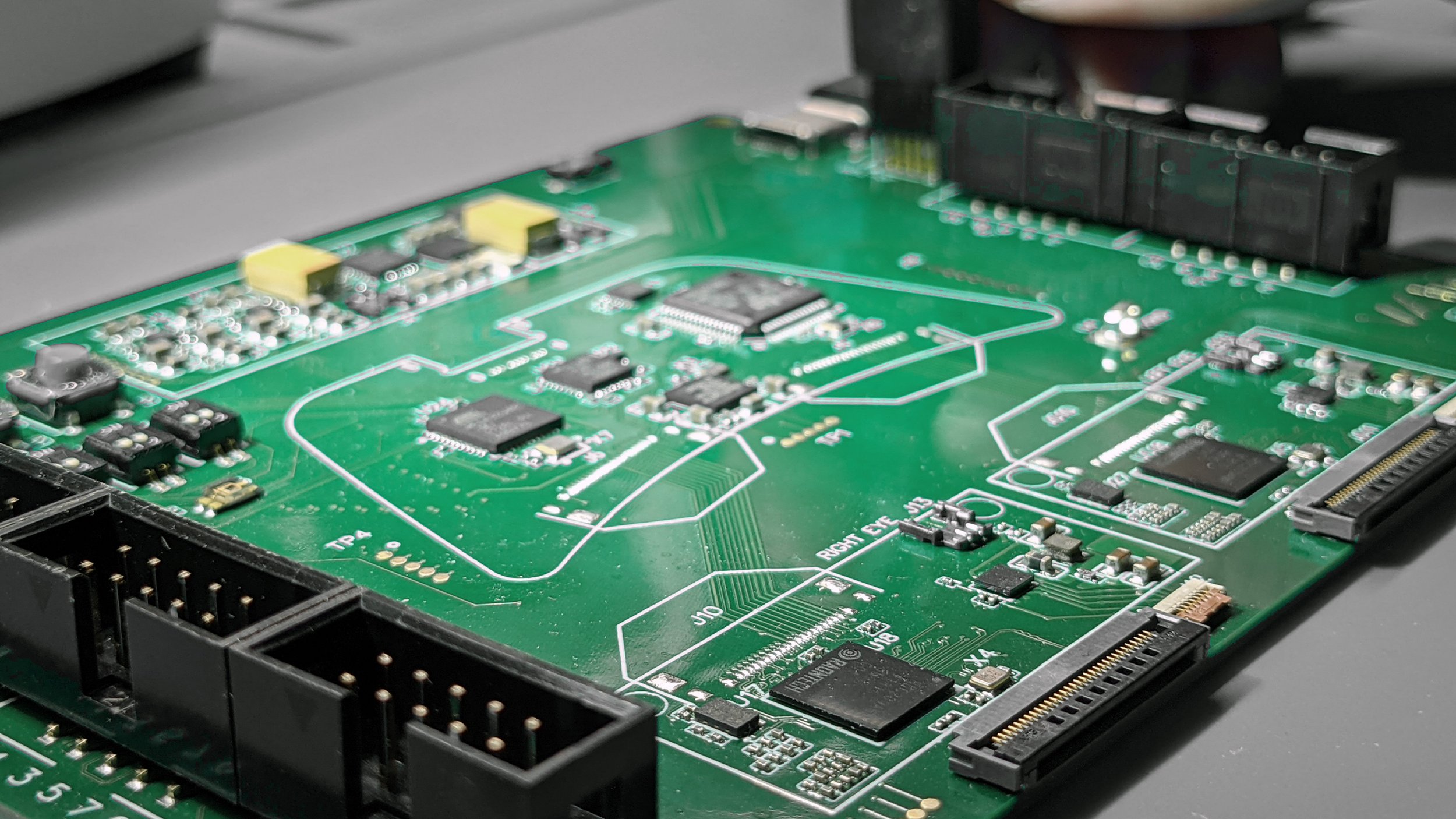

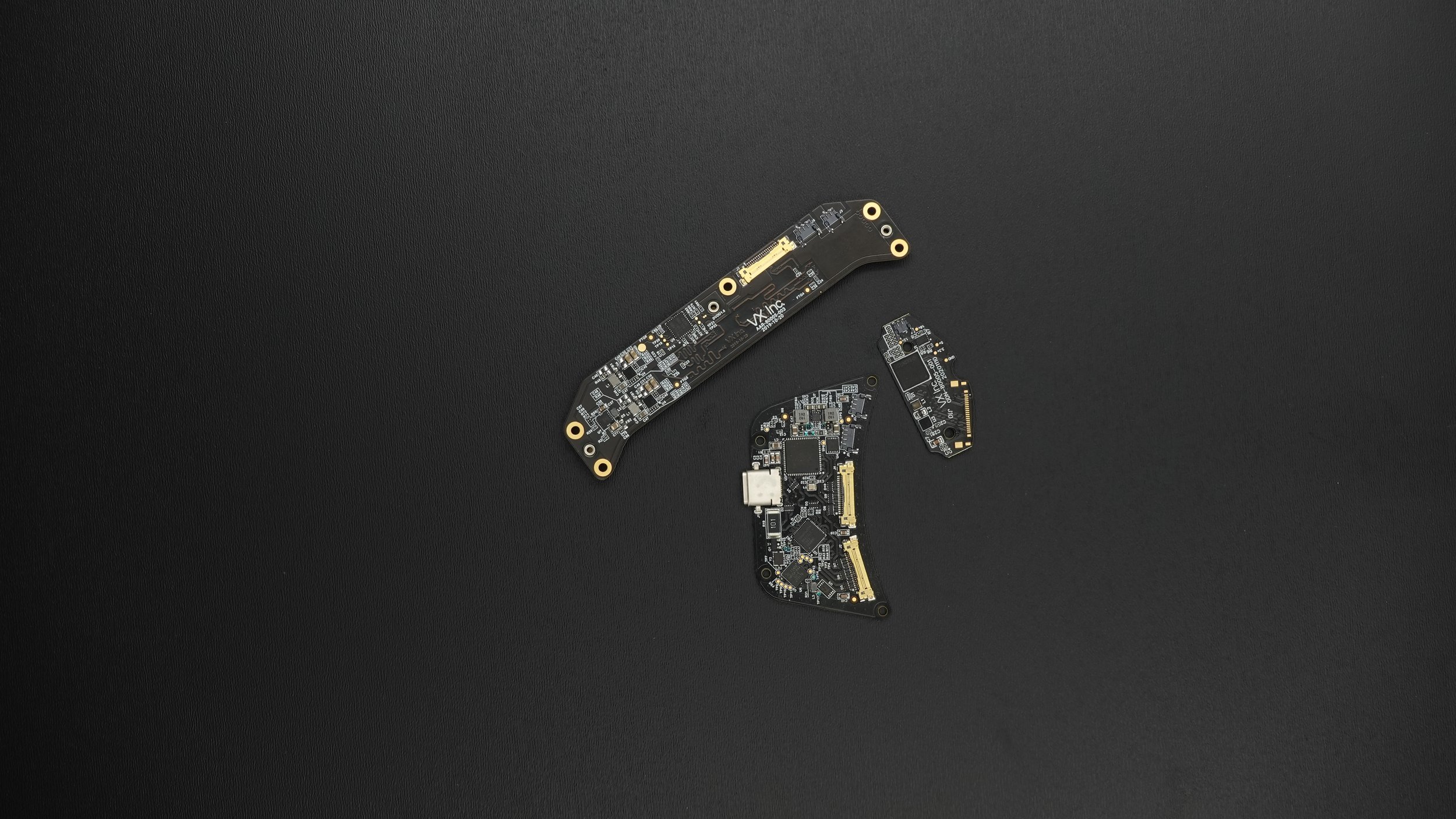

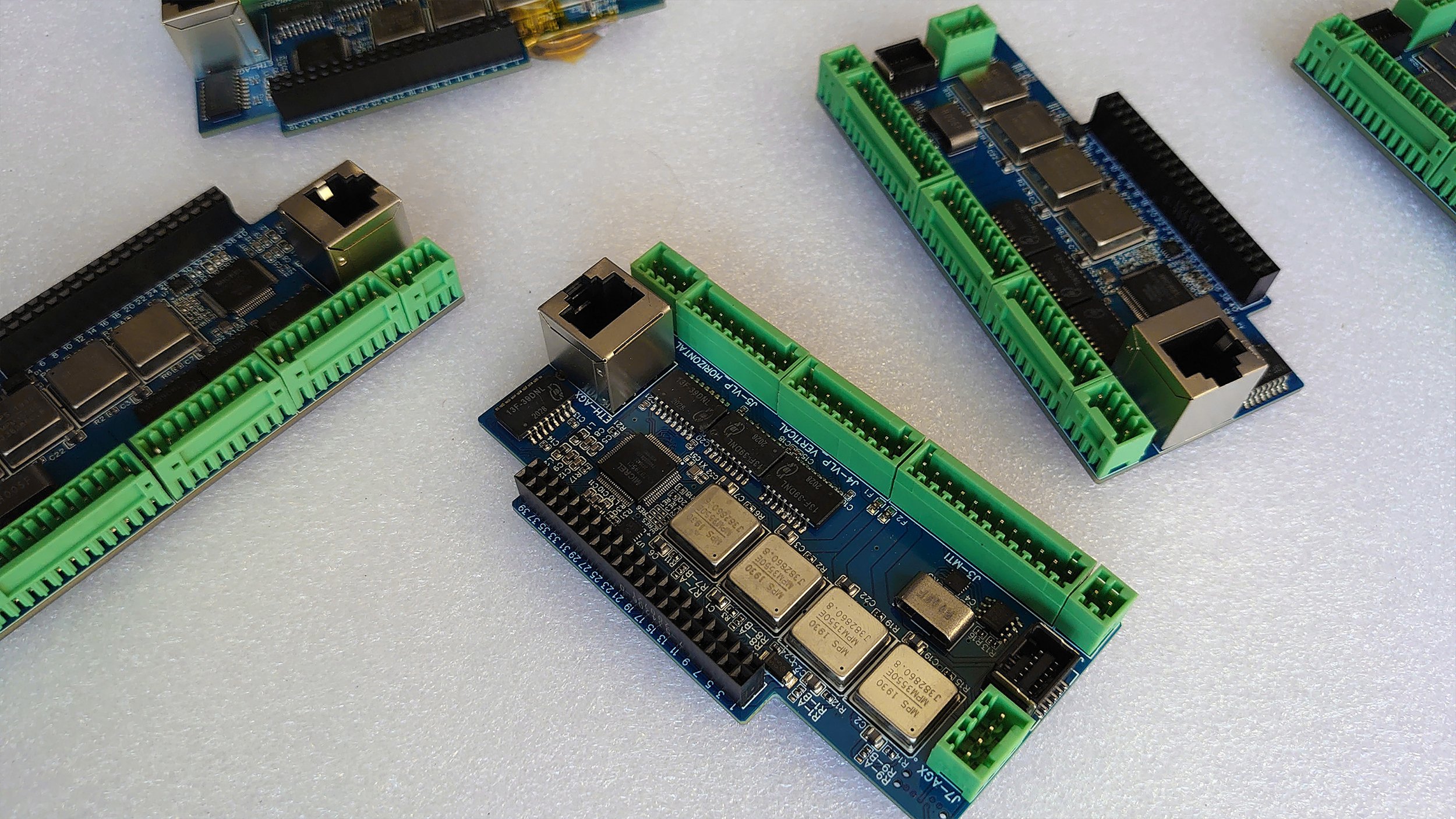

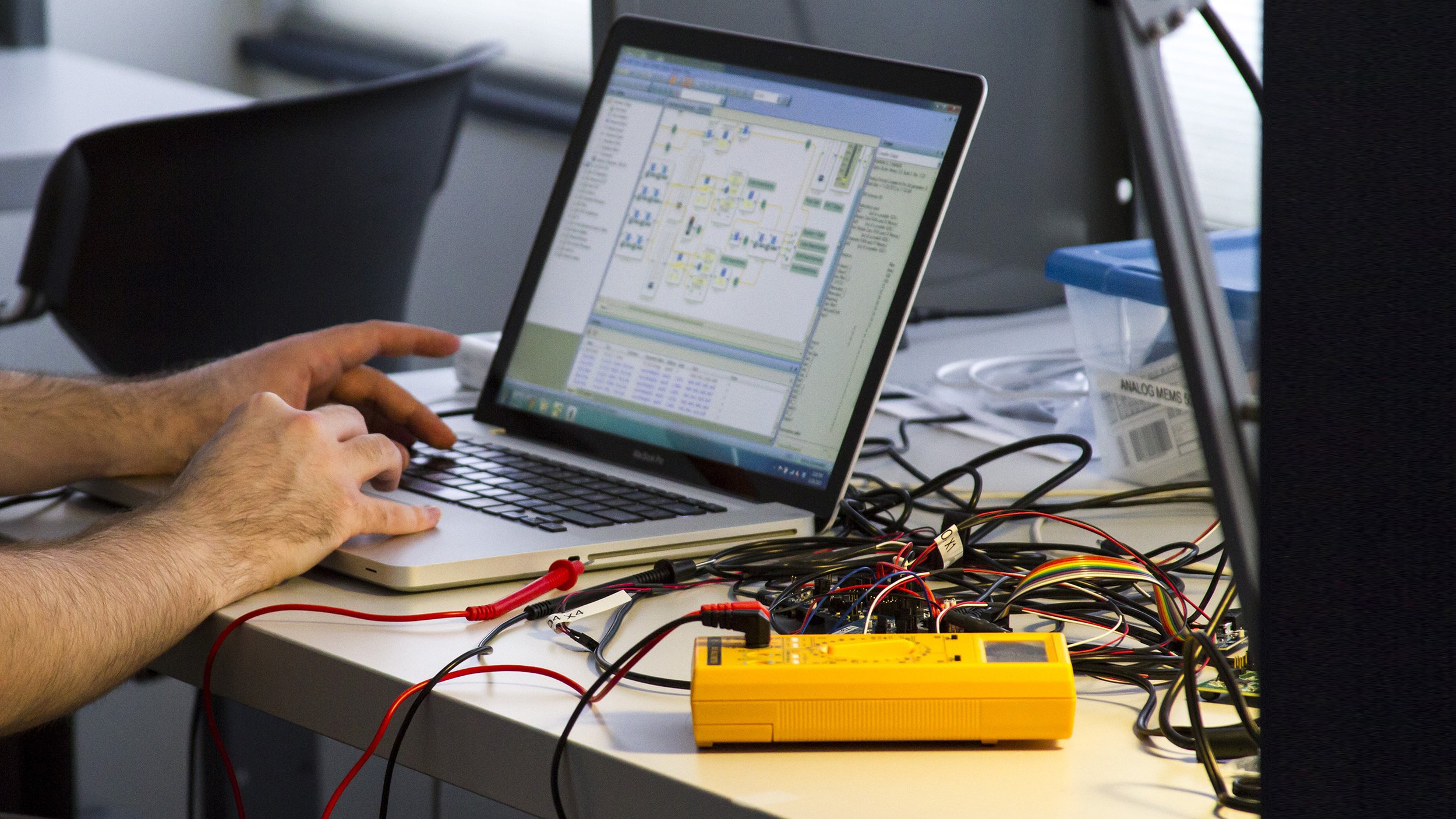

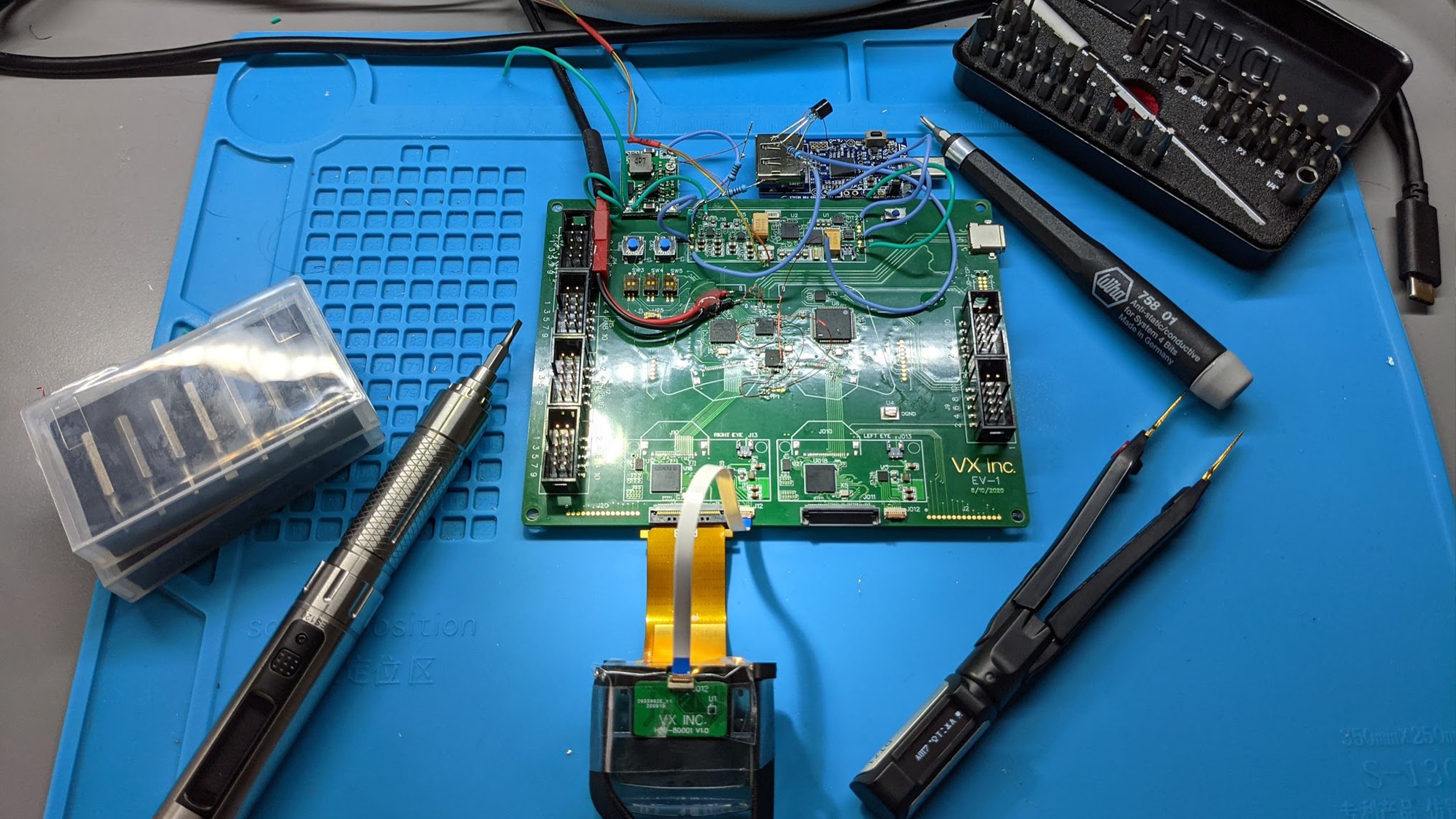

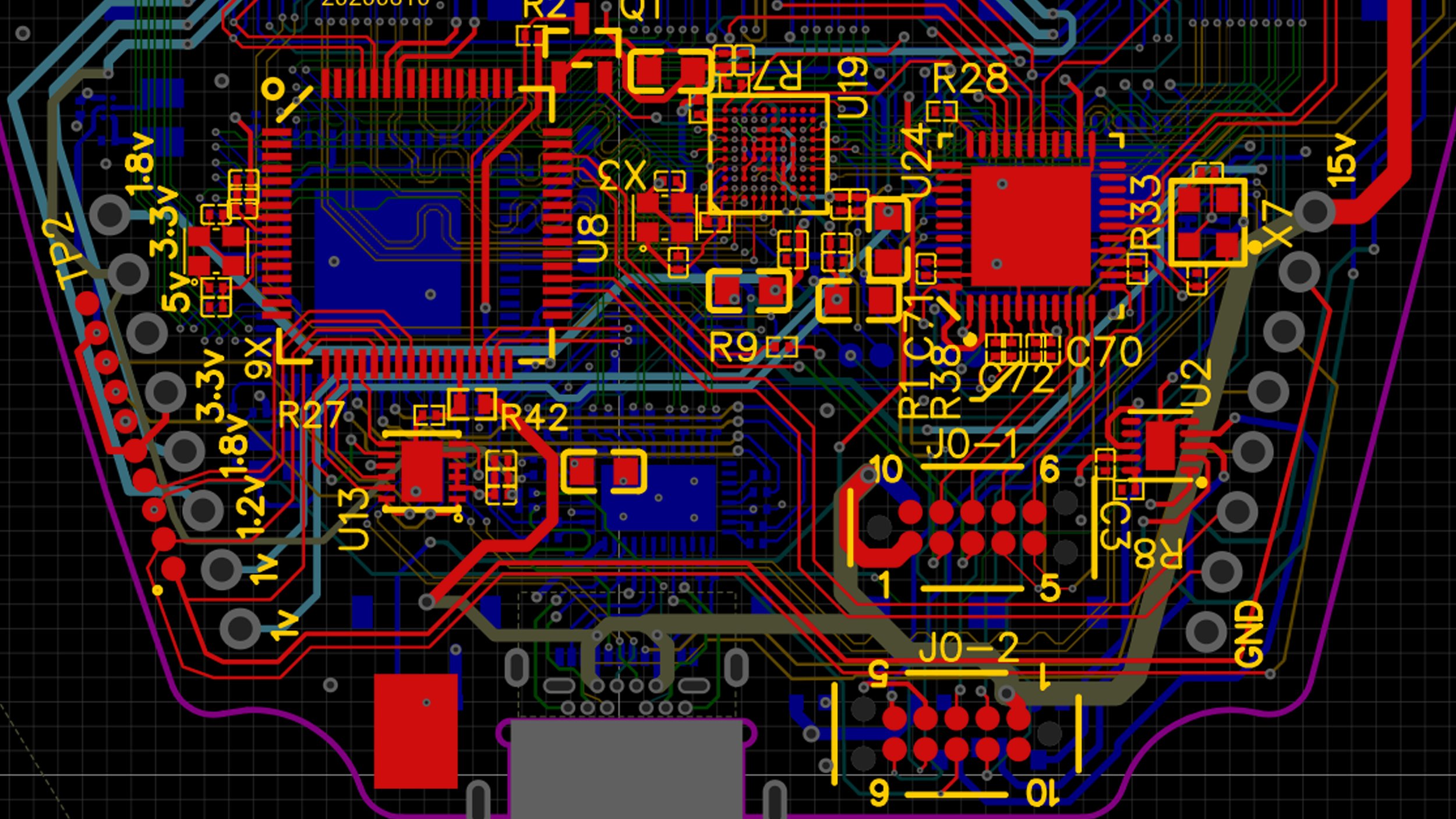

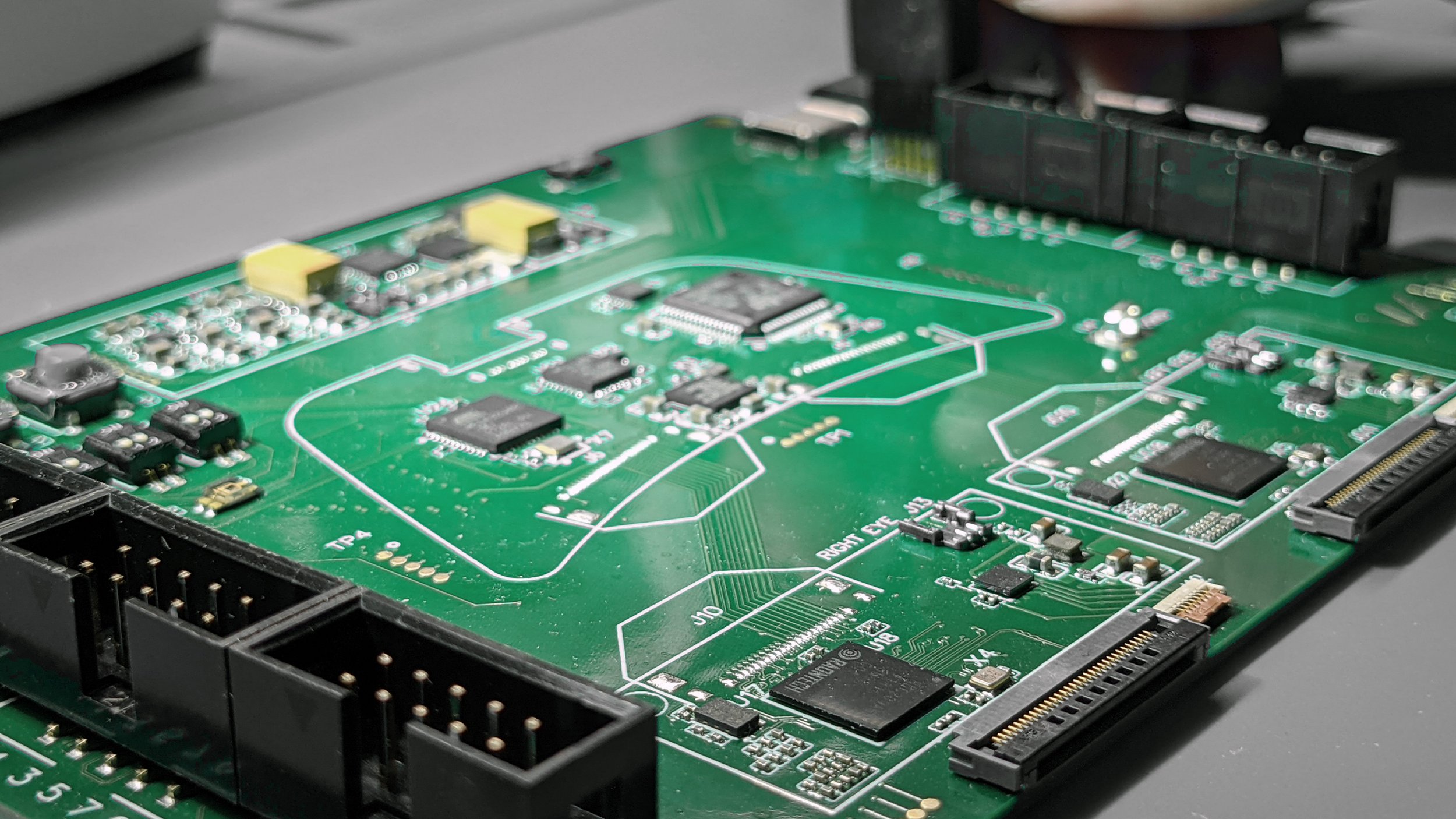

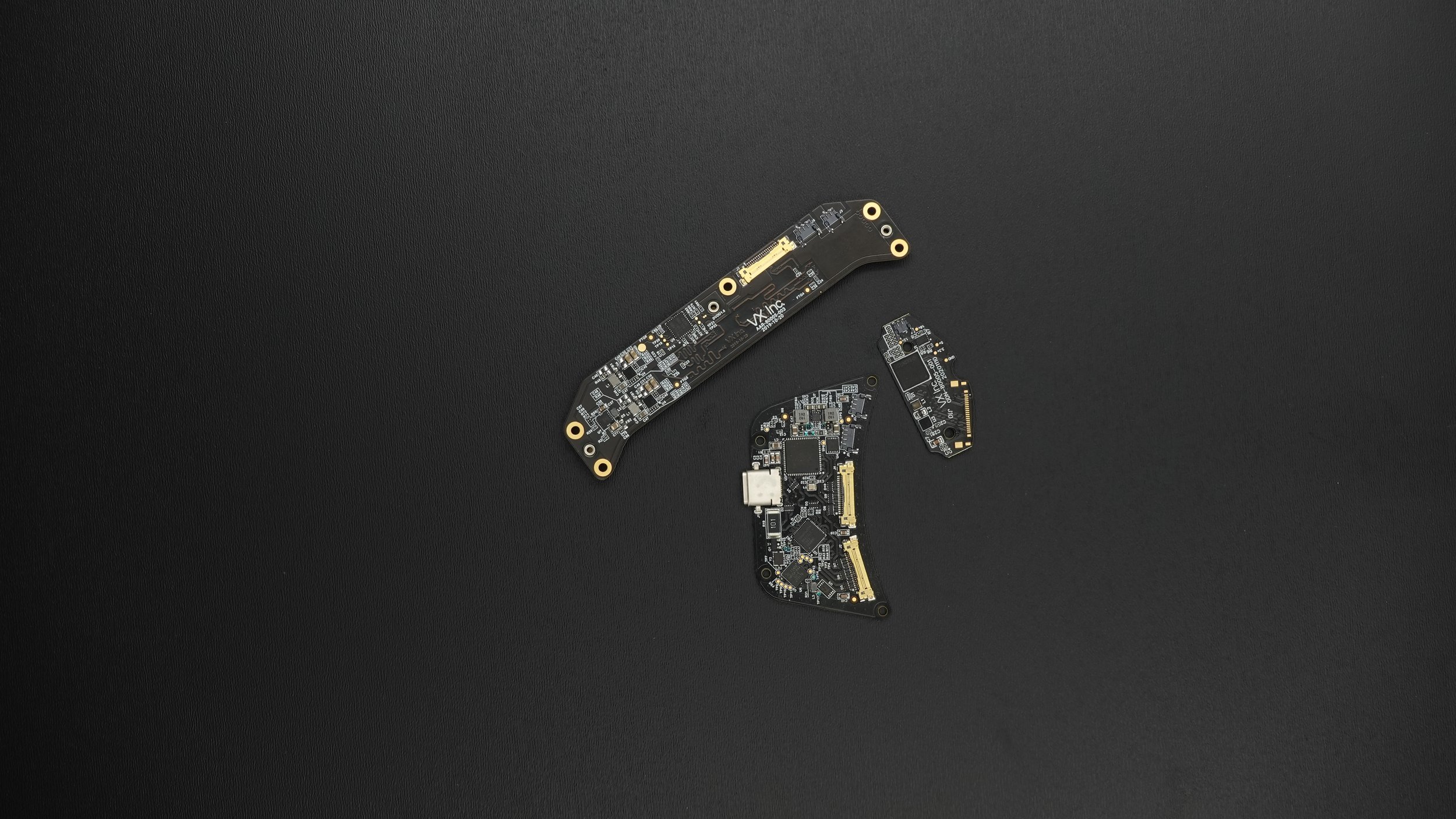

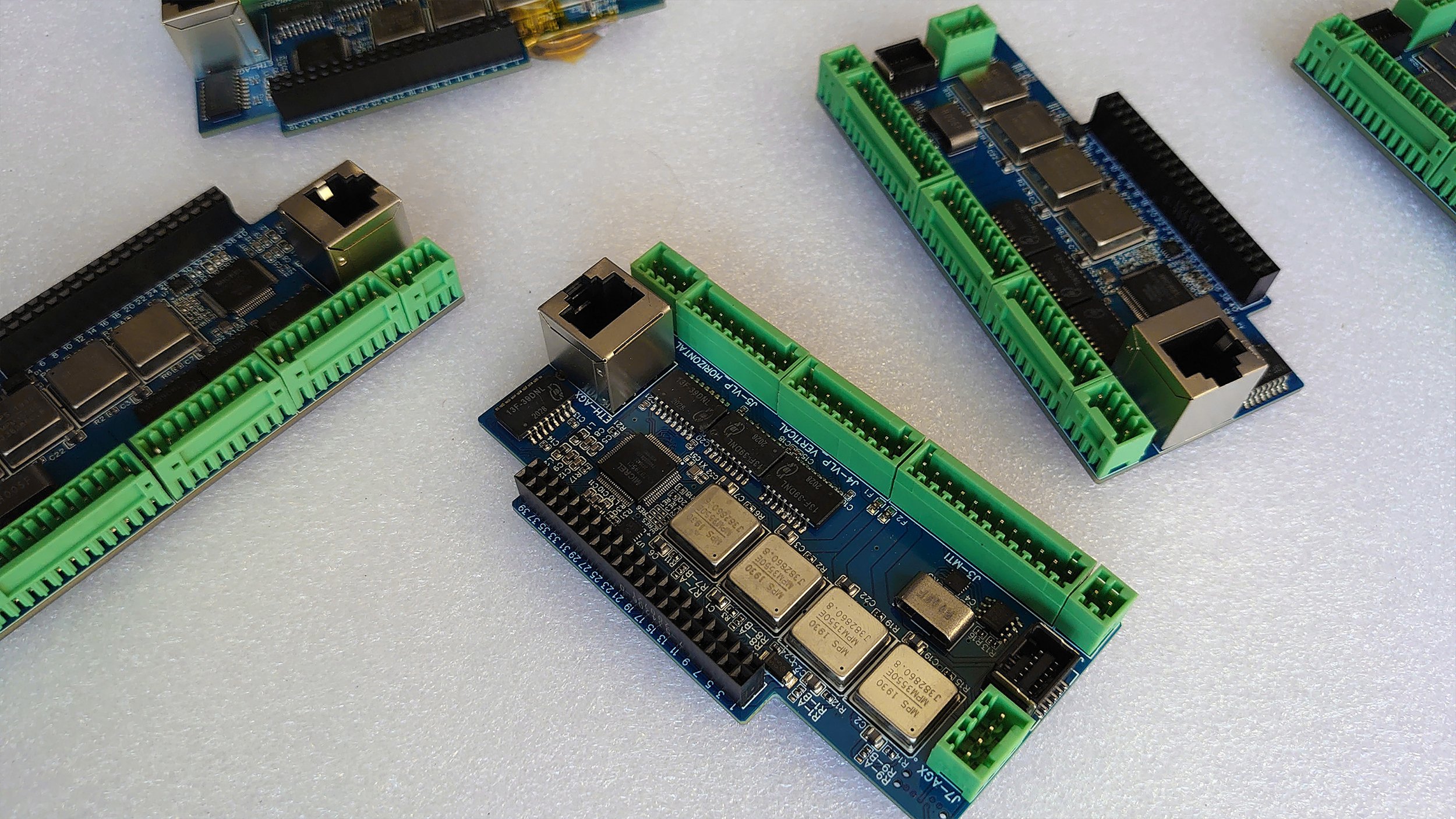

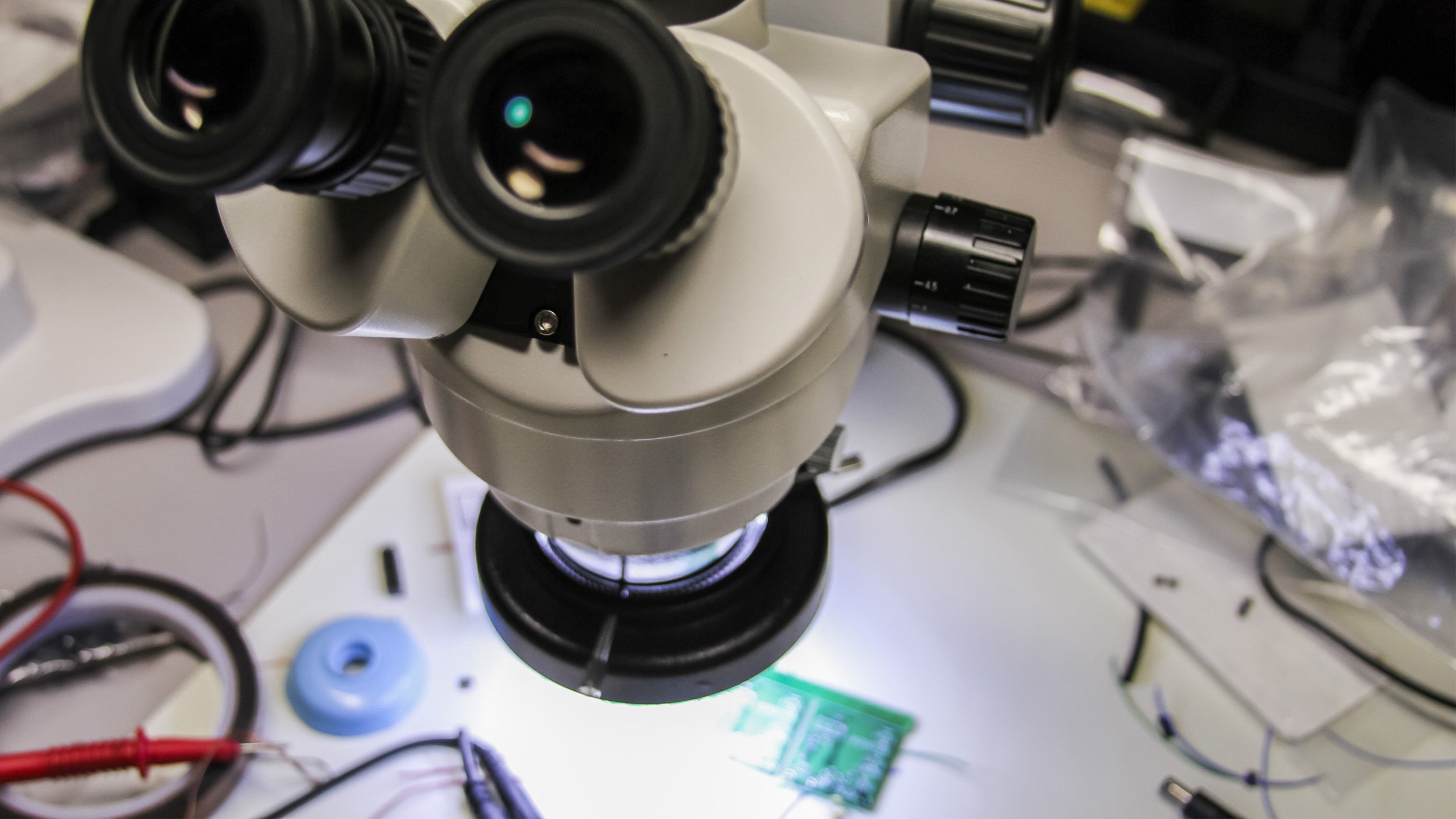

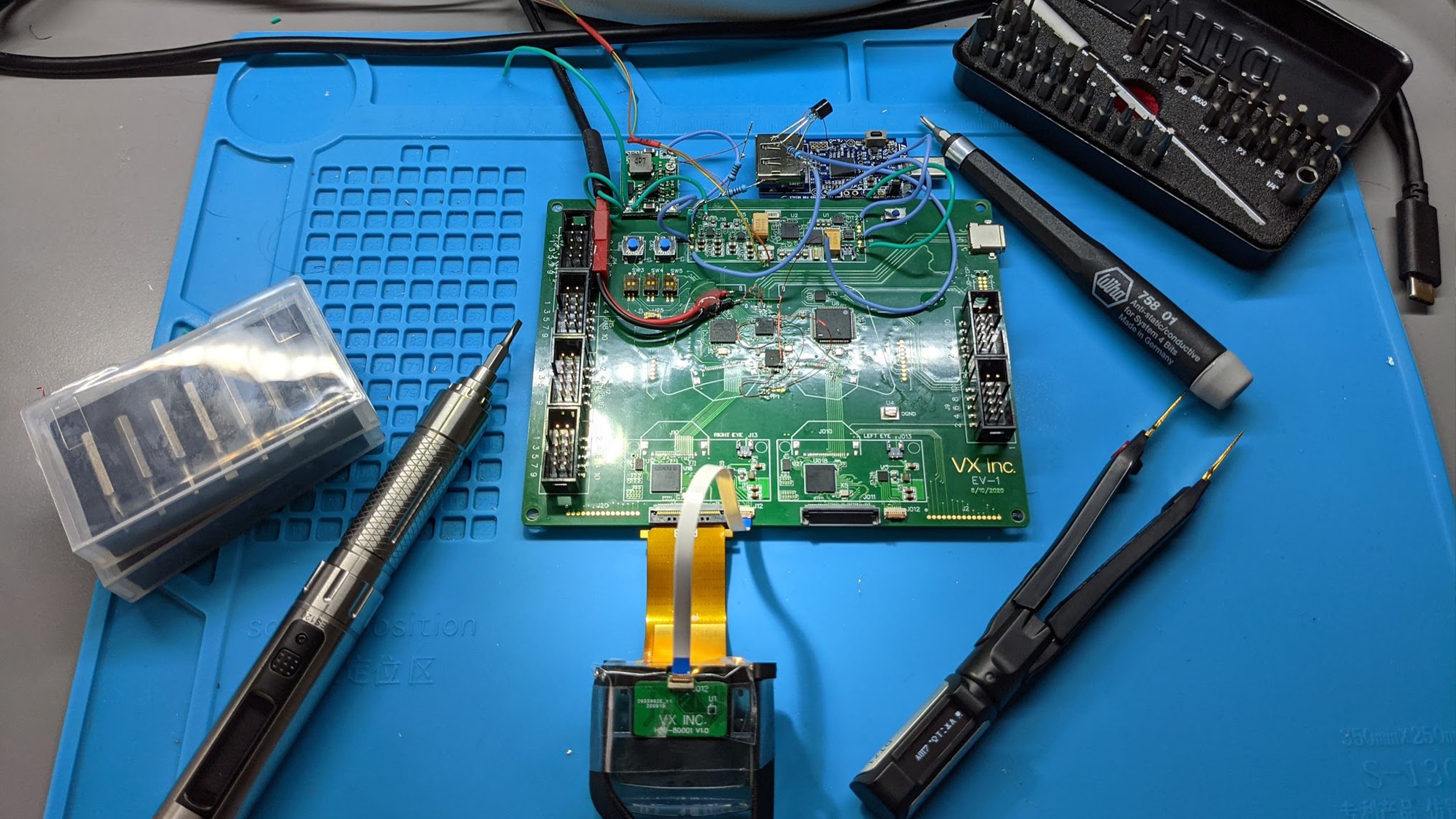

Electrical Engineering

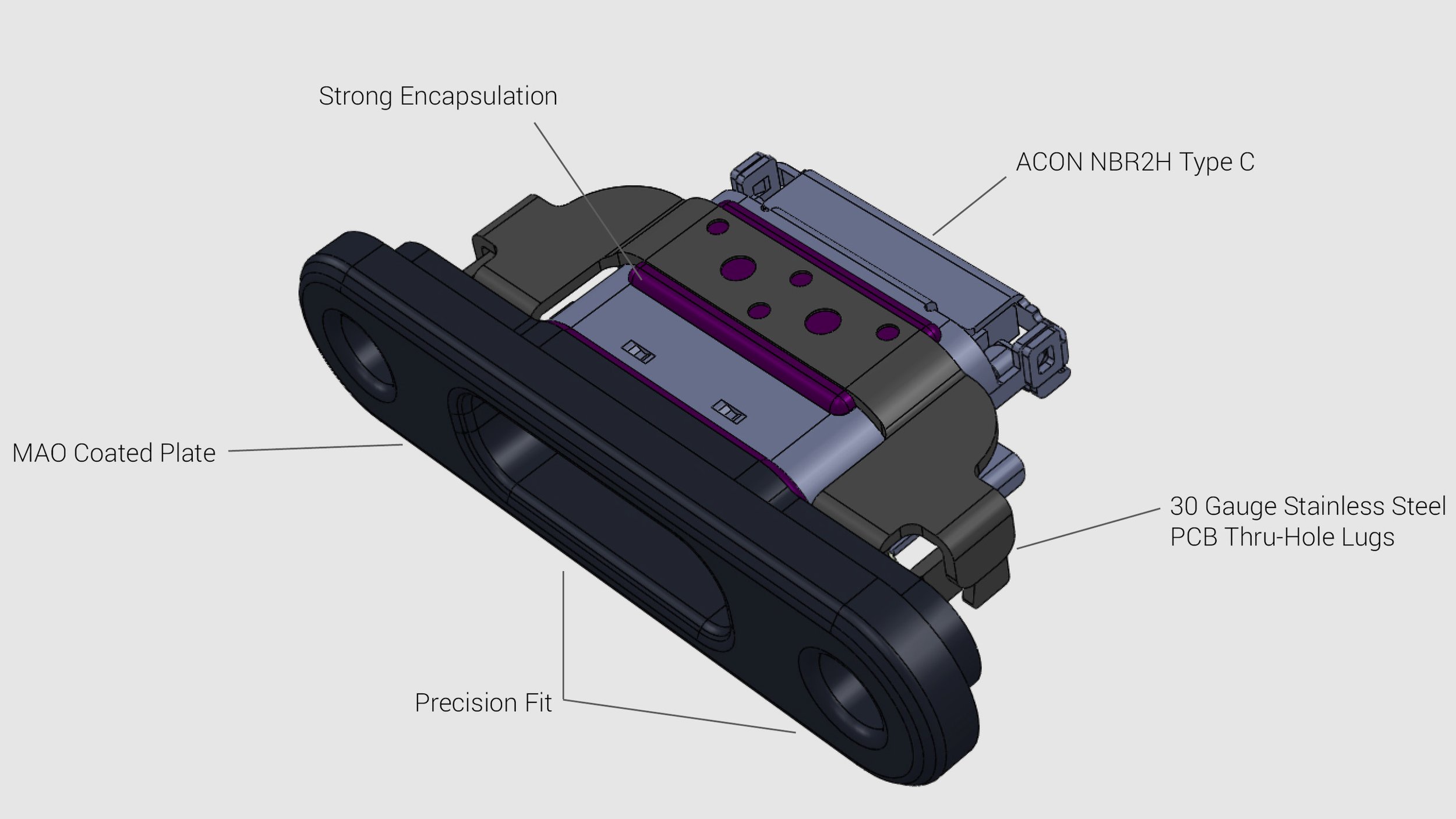

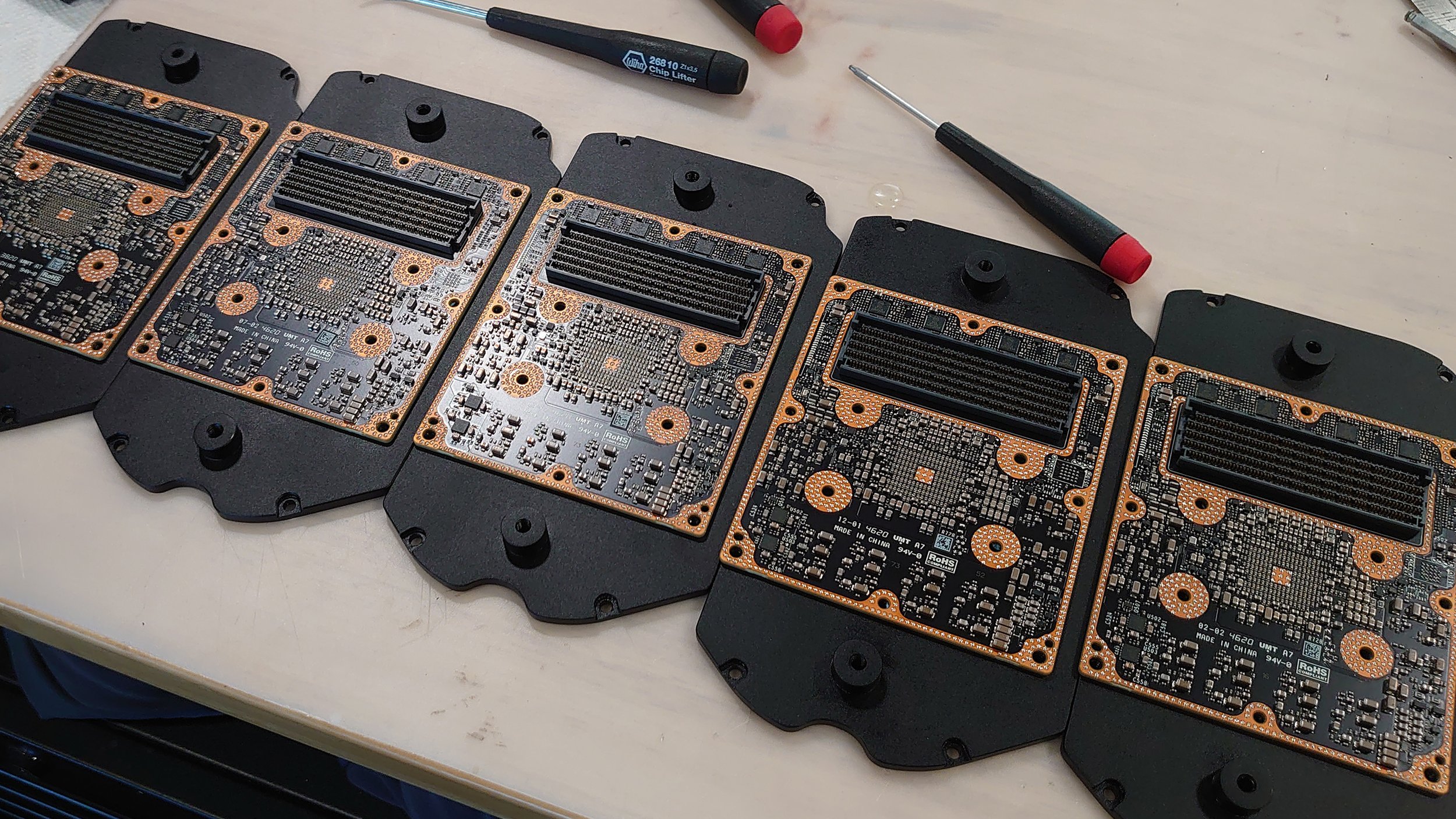

Our electronic designs uses proven methodologies, the latest standards, and validated hardware. Our boards meet global fabrication standards for on-shore and off-shore supply chain choice.

We don’t just layout boards - we provide full BSP, firmware, and board-level software. Our knowledge and licensed code get custom electronics up and running fast.

RHoS, FCC, CE, UL, DFARS Compliant

Small form-factor PCB design

High-density layout

1000+ component systems

USB Type-C, MIPI DSI, MIPI CSI

Multi-layer, HDI, Flex, Flex-Rigid, and Signal Integrity

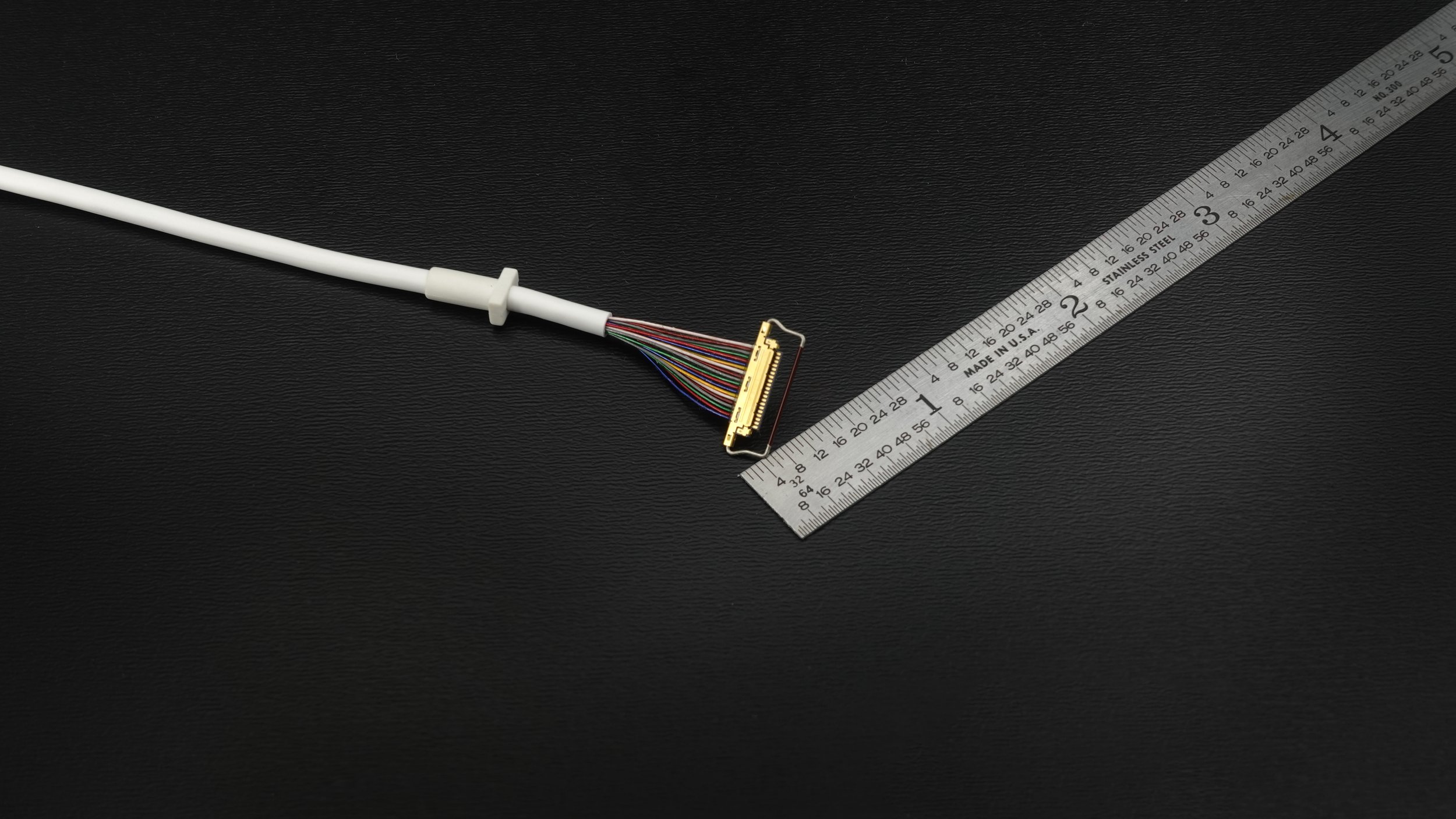

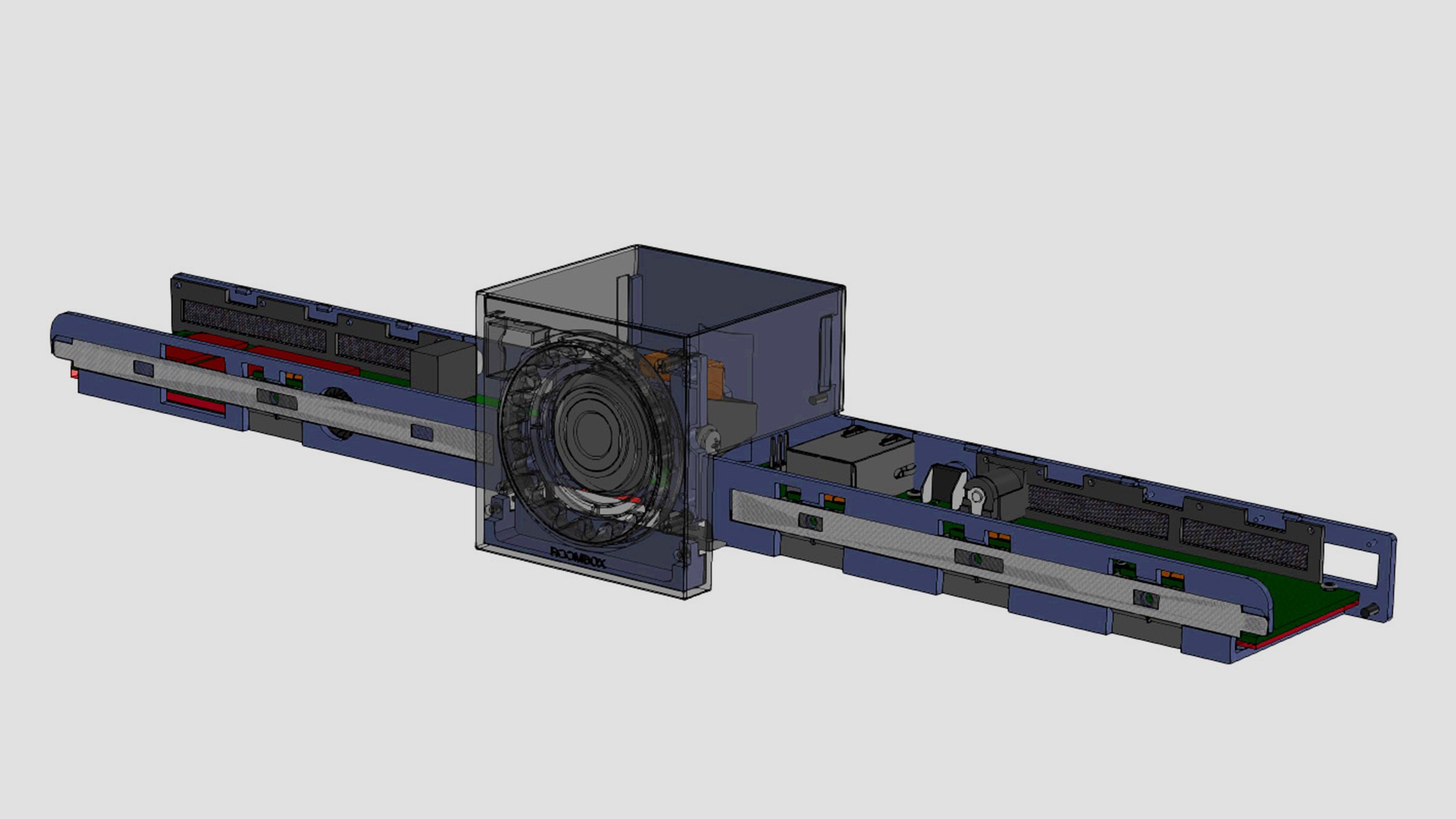

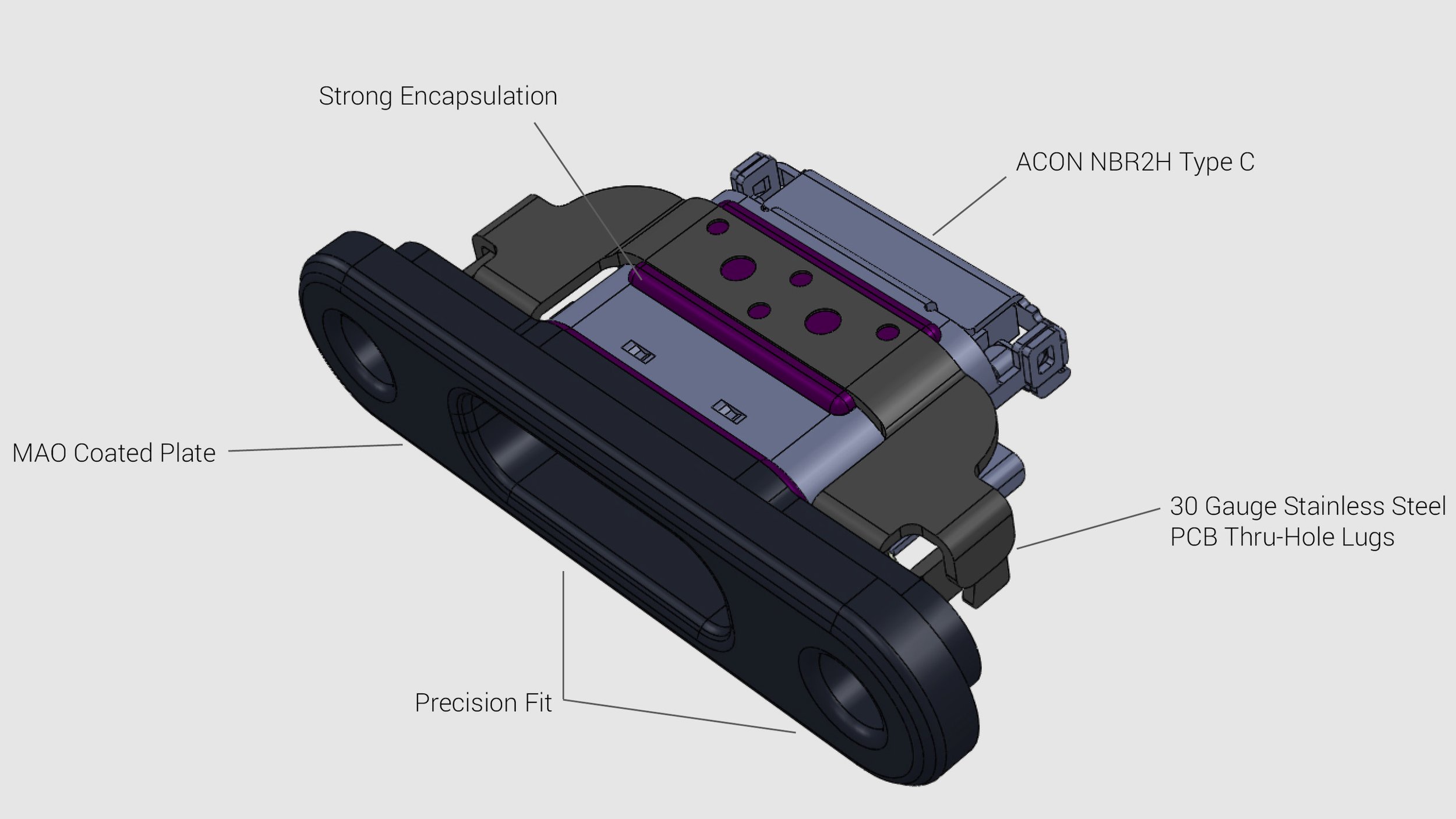

System Integration

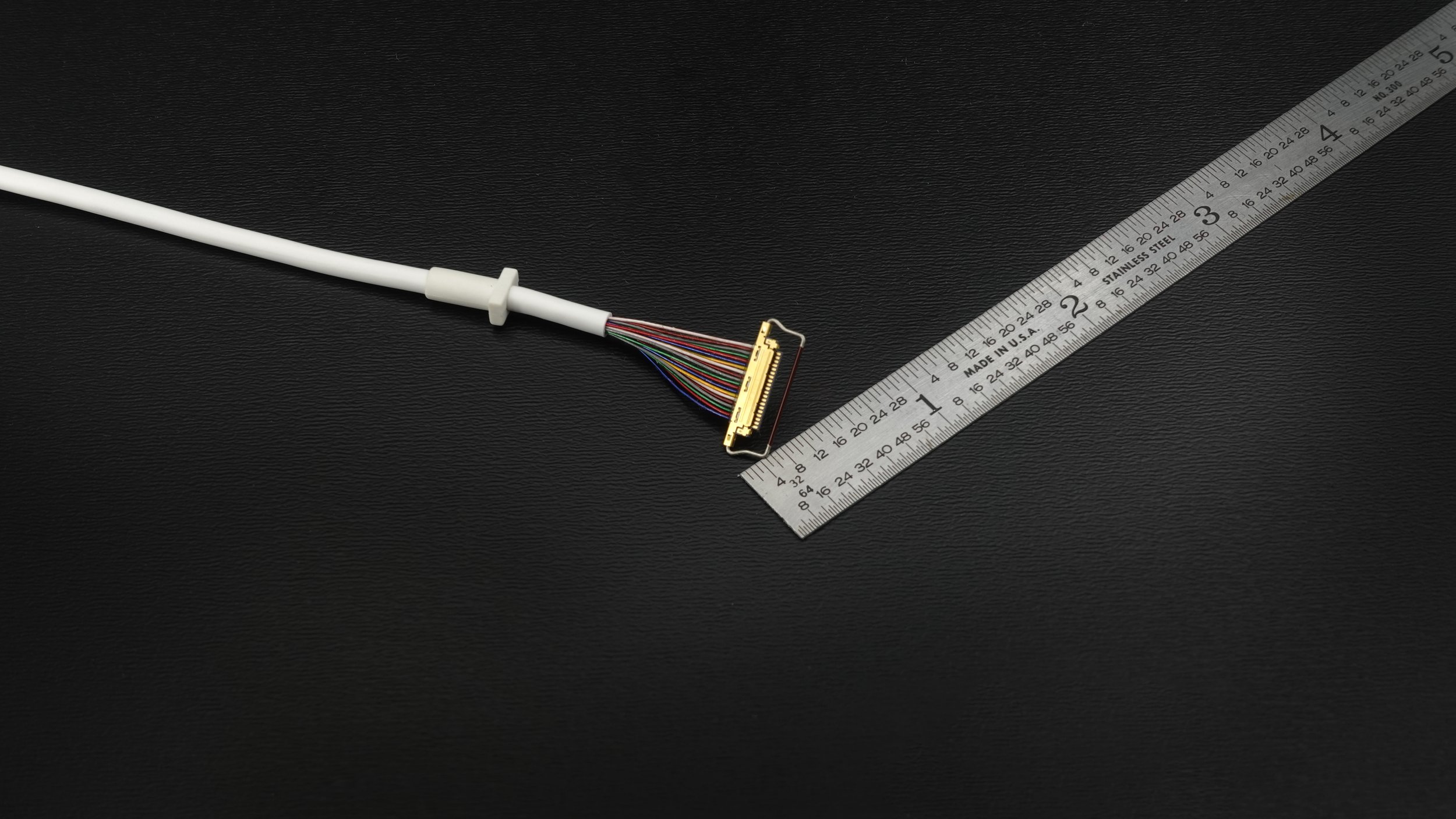

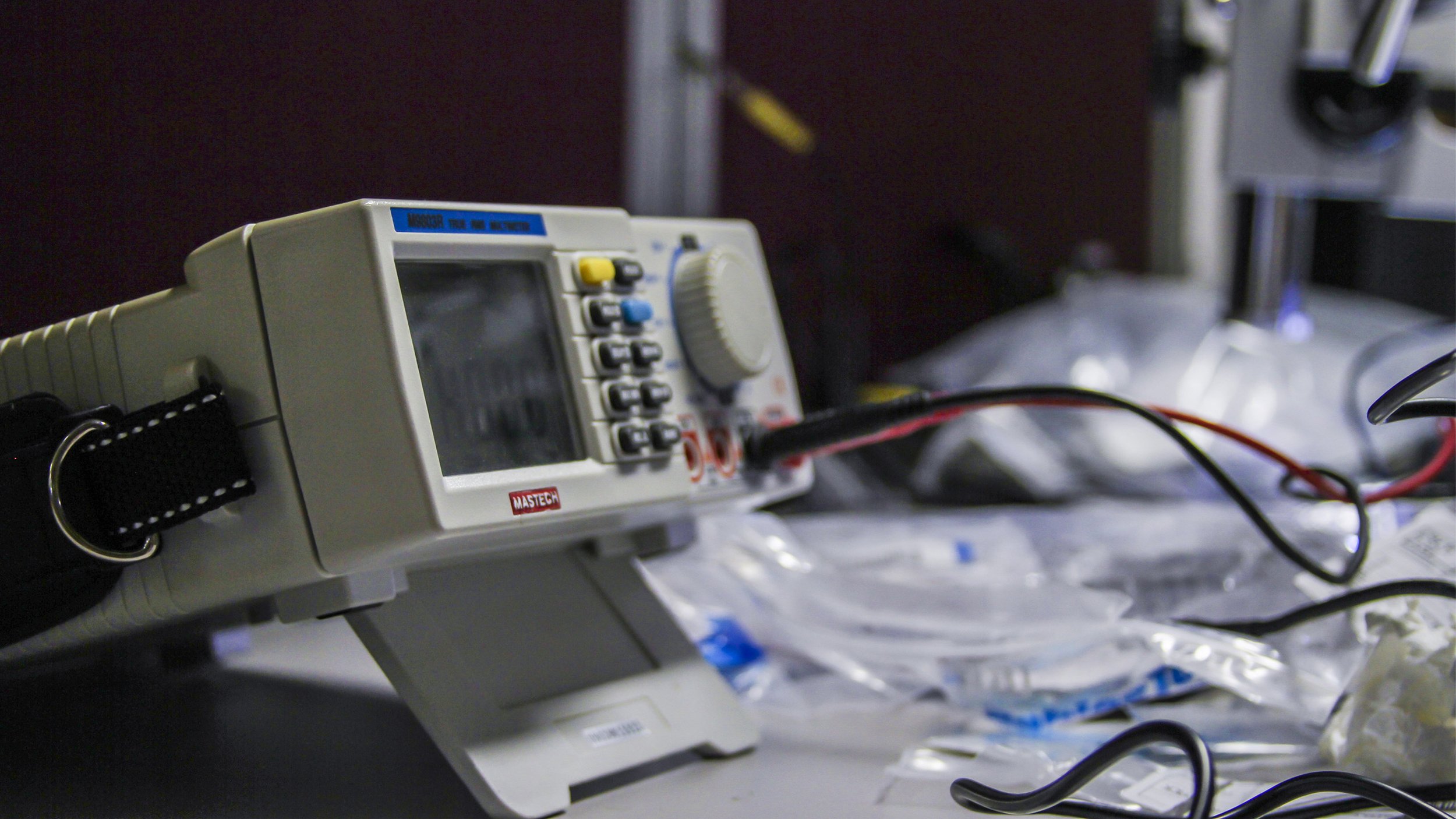

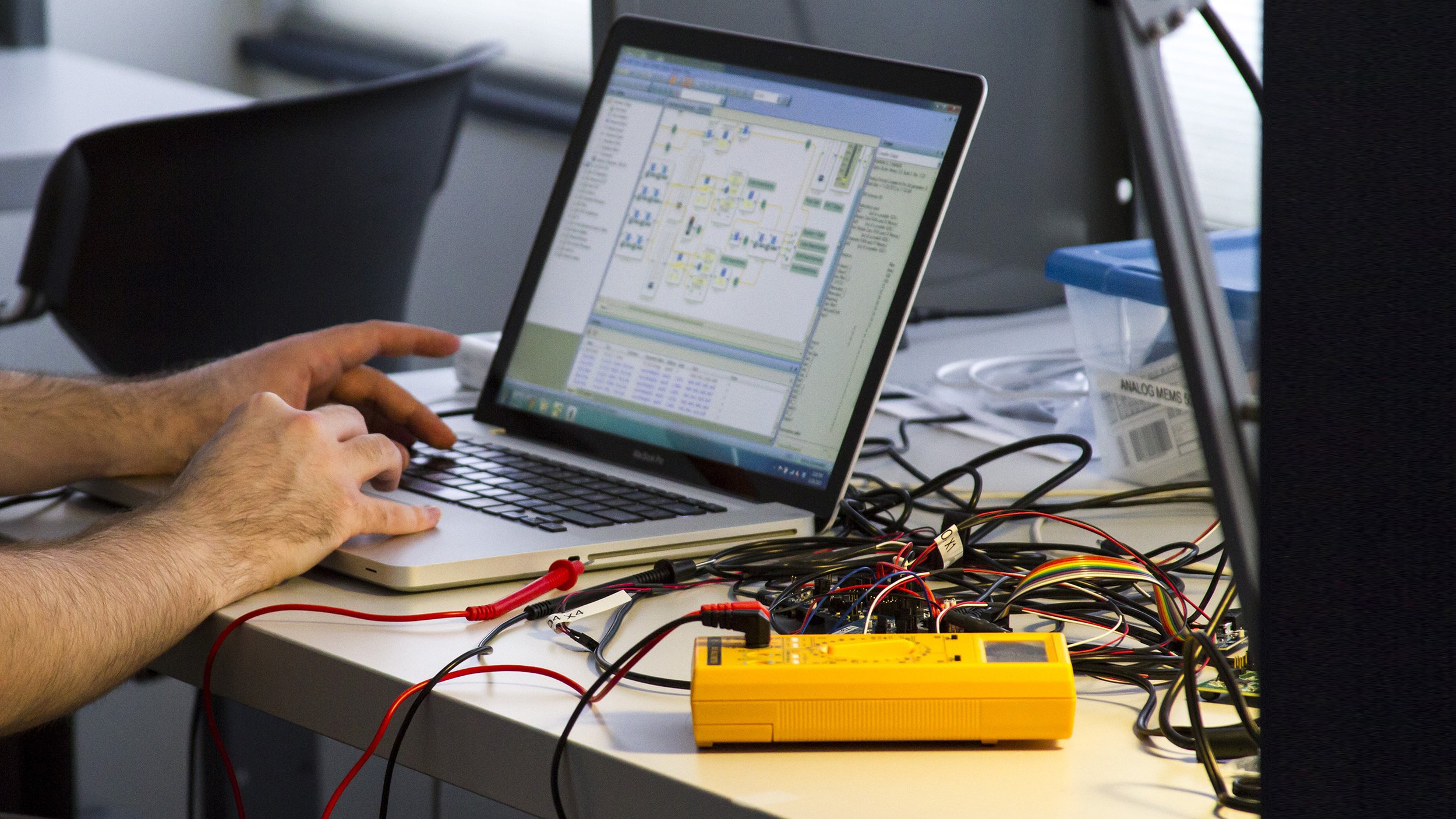

We provide easy system integration of technology into products. We have a diverse range of industry partners for sensors, cameras, APUs, and controllers for miniaturization and performance.

We use a proven eCAD to mCAD process allowing our engineers to create a design of interrelated parts and features in real-time collaboration. Every mission critical detail, from the enclosure, down to the wire harness, is designed to function as a complete system.

Engineering controls to prevent time and cost over-runs

Phased Validation Testing

Resilience Planning

SLAM, Depth, Lidar, Thermal, 3D Mapping

Wire harness and cable design

Assembly fixturing and calibration

Industrial Design

A good industrial design is key to make any produced product come to life. Good design can define a product, maximize profit and boost sales.

We offer a full range of design, product planning, concept rendering, and human factors services.

Design Focused Manufacturing

User Experience

Concept Ideation

3D Rendering

Human Factors

Color, Material, Finish

Mechanical Engineering

Our engineers are development experts with a passion for good design, electromechanics, optomechanics, and advanced manufacturing.

Our broad expertise allows us to design, analyze, fabricate, and test complicated mechanical systems. We specialize in compact, rugged, and harsh environment devices.

Design for Manufacturing and Assembly

3D Modeling and 2D Drawings

Manufacturing Packages

Tooling Design

IP6X, Z87, MIL-PRF, UL…

Electrical Engineering

Our electronic designs uses proven methodologies, the latest standards, and validated hardware. Our boards meet global fabrication standards for on-shore and off-shore supply chain choice.

We don’t just layout boards - we provide full BSP, firmware, and board-level software. Our knowledge and licensed code get custom electronics up and running fast.

RHoS, FCC, CE, UL, DFARS Compliant

Small form-factor PCB design

High-density layout

USB Type-C, MIPI DSI, MIPI CSI

Multi-layer, HDI, Flex, Flex-Rigid, and Signal Integrity

System Integration

We provide easy system integration of technology into products. We have a diverse range of industry partners for sensors, cameras, APUs, and controllers for miniaturization and performance.

We use a proven eCAD to mCAD process allowing our engineers to create a design of interrelated parts and features in real-time collaboration. Every mission critical detail, from the enclosure, down to the wire harness, is designed to function as a complete system.

Engineering controls to prevent time and cost over-runs

Phased Validation Testing

Resilience Planning

SLAM, Depth, Lidar, Thermal, 3D Mapping

Wire harness and cable design

Assembly fixturing and calibration

Our Process Ships Your Product Fast

Proper expectations are key.

We will work with your stakeholders to understand your product needs. Our Features-First, Top-Down, Outside-In, design methodology allows for a fast and straightforward path to market.

Top-Down allows us to have a defined scope and allows us to work fast. Outside-in allows you to have visibility of what the product will look like from the beginning.

When finished, we will have created a design of interrelated parts and features that work towards the product as a whole.

Features-First means we start with a wishlist of features requested by project stakeholders. This list is then refined and divided into two categories. The first is “required features”, and the second is “nice to have features”. These features will be added to a Product Requirements Document (PRD).

Top-Down means we work in a hierarchical fashion to define a form factor. We start by placing known components in the system, arranging them based on the requirement of use. In the case of an HMD, we will design around first, the eyes, second, the head, third, the near eye display, and will continue this down to the least defining features and components.

Outside-In means parts are designed from the outer form factor and working inward. The shape of the form factor is divided up into sub-assemblies, parts, and lastly the part features. This method of creating part features allows for changes to be made even after some parts are locked.

Contact Us

It would be our privilege to partner with you in the creation of something truly extraordinary.

Ready to get started?

Use the form or give us a call to meet our team and discuss your project and business goals.

We can’t wait to meet you!

Email Us:

info@vx-inc.com

Find Us:

320 Newport Way NW

BLDG: B

Issaquah, WA 98027